VOC Analysis in Contact Packaging Materials Using the HT3 Automated Headspace Analyser

INTRODUCTION

Regulatory agencies such as the United States Food and Drug Administration (USFDA) and the European Union (EU) have published regulations and provided guidance on the use of chemicals in food packaging materials. SCION Instruments provides method parameters for the HT3 Automated Headspace Analyser for VOC analysis of volatile compounds that may be contained in food contact packaging materials under various conditions.

VOC analysis of food involves the identification and quantification of volatile compounds present in food products. This analytical process is crucial for assessing the quality, safety, and authenticity of food, as VOCs contribute to the aroma, flavor, and overall chemical composition. Monitoring VOCs aids in detecting potential contaminants, evaluating freshness, and ensuring adherence to quality standards, thereby enhancing food safety and consumer satisfaction.

In this analysis both temperature and mixing parameters were investigated to determine which Volatile Organic Compounds (VOC’s) may be released when subjected to these conditions.

Figure 1. SCION HT3 Headspace Sampler together with the SCION Instruments 8300 GC platform in combination with to 8700 SQ-MS.

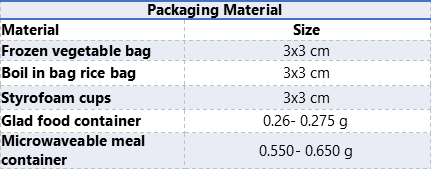

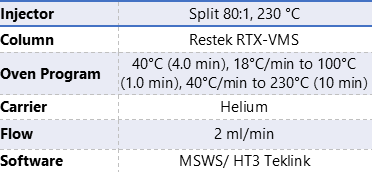

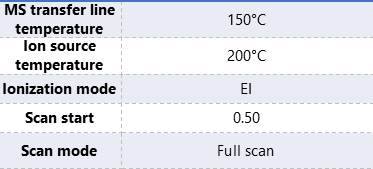

The SCION Instruments 8300 GC in combination with the 8700 SQ-MS and HT3 automated headspace analyser were used for the analysis of several food contact packaging materials. Various contact packaging materials were investigated for this poster and the products as well as sample size are presented in Table 1. Samples were added directly to a 22mL headspace vial. This vial was then sealed and placed onto the autosampler for analysis. The GC/MS parameters for all sample materials remained constant and are presented below in Tables 2. The HT3 Automated Headspace Analyzer ran in the static mode while two parameters were varied, the Sample Platen Temperature and Sample Mixing (On or Off), these parameters are also presented in Table 2. Sample mixing remained constant at Level 5 and was employed to assist releasing possible VOC’s from the solid materials.

Table 1. Contact packaging material sample information

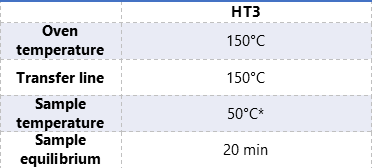

Table 2. Instrumentation operating conditions.

DATA COLLECTION AND DISCUSSION

Adequate and uniform sample sizes for each product analysed were determined either by size or weight to maintain uniformity among sample aliquots. Heating at various temperatures was investigated as most products require heating the contents prior to consumption. Previous literature indicates that 100°C is used to mimic optimal heating as this is the boiling point of water. For this study Platen Sample Temperature ranges of 50,100,150,200 and 250°C for all packaging materials were investigated. Analysis for samples below 100°C indicated poor response while the higher more extreme temperatures caused the material to char within the vials thus rendering the chromatographic results inconclusive, therefore as expected the optimum temperature of 100°C was selected as a representation for the materials investigated.

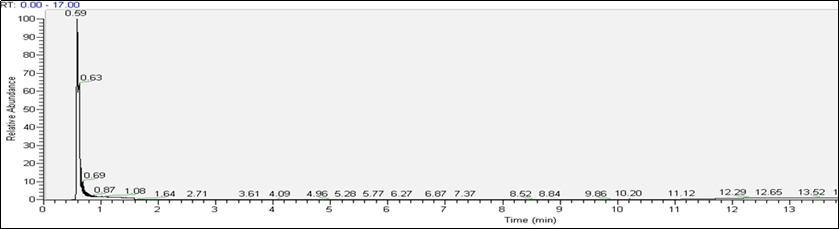

Seven replicates were analyzed at 40°C as a baseline to determine if any VOC’s were emitted from the products prior to heating. Several blanks were run prior to each contact packing analysis batch to ensure system cleanliness prior to material analysis. A representative chromatogram for a typical blank is provided in Figure 2. All five packaging materials produced their own unique chromatograms at the optimum temperature of 100°C and are presented in Figures 3-7. The majority of compounds present in the materials investigated were; alcohols, ketones and branched and straight chained hydrocarbons. The presence of 2-pentanone, also known as methyl propyl ketone, was found in four of the five packaging products investigated. 2- pentanone is sometimes used in very small amounts as a flavouring food additive. Two other ketones, 3-pentanone and methyl isopropyl ketone are isomers of 2-pentanone. Identification of the major peaks in each chromatographic representation was performed using the NIST library database.

Figure 2. Typical blank run prior to each analysis

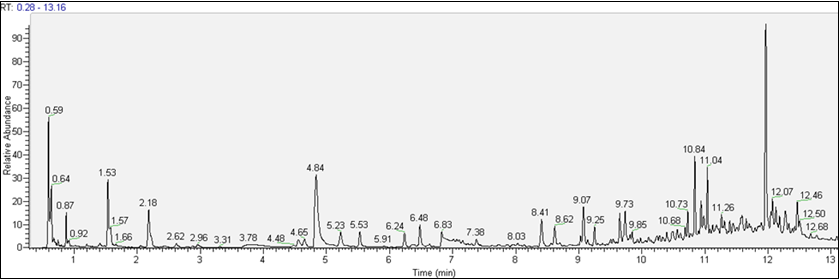

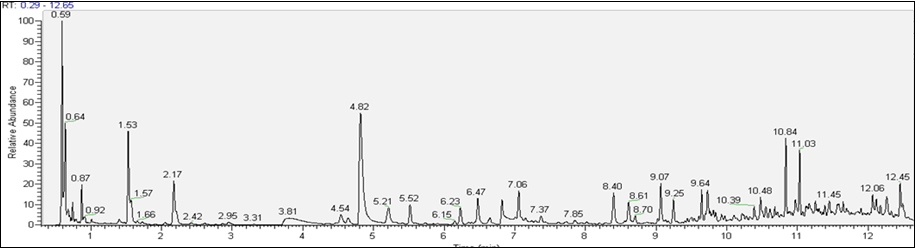

Figure 3. Frozen vegetable bag

Notable for the frozen vegetable bag was the presence acetone at 1.53 minutes and methacrolein at 2.18 minutes. Methacrolein is an unsaturated aldehyde used in the manufacture of polymers or resins.

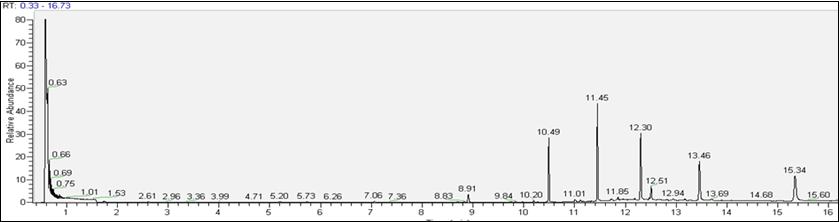

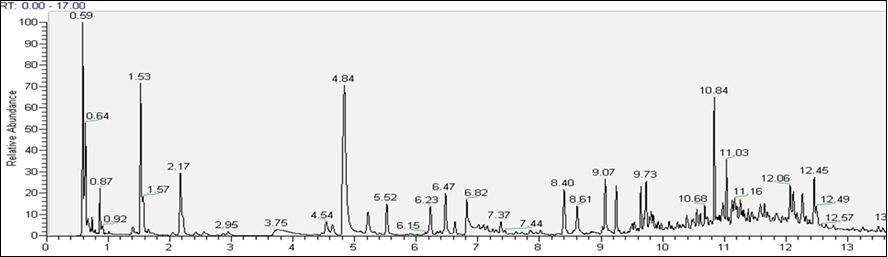

Figure 4. Boil in bag rice

The late eluting peaks between 10-13 minutes for the boil in the bag rice packaging were deodecane, tridecane, tetradecane, pentadecane and hexadecane respectively.

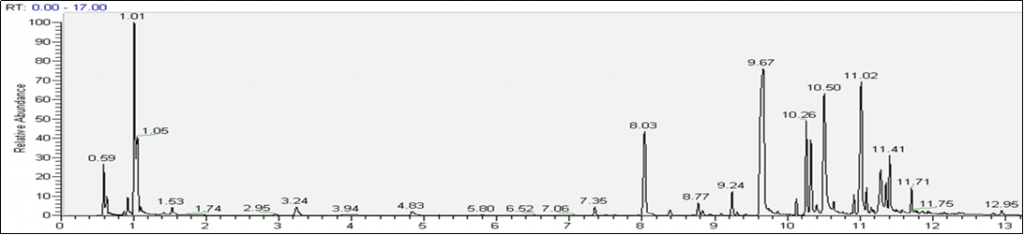

Figure 5. Styrofoam cups

Styrene, as expected, eluted at the retention time of 9.24. Also notable is the presence of benzene at 3.24 and phenol is also present at 10.26

Figure 6. Commercial food container (Lid)

As expected the presence of methacrolein at 2.17 minutes was also observed in the commercial food container. acetone is seen in this packaging material as well at 1.53 minutes.

Figure 7. Microwaveable meal bowl

Notable for the microwaveable meal container is the presence of long chain hydrocarbons; methyl heptane, trimethyl hexane, dimethyl heptene from 5.10-7.01 minutes.

CONCLUSION

The HT3 Automated Headspace Analyzer performed well in the static mode for analyzing solvents in food packaging materials. Chromatographically many of the identified peaks for all the contact packaging material analyzed for this poster were branched and unbranched hydrocarbons from C6 through C18. Additionally many alcohols, ketones, trace amounts of aromatics such as phenol and low-level VOC’s such as 2-butanone and benzene were identified. The late eluting peaks between 10-13 minutes for the boil in the bag rice packaging (alkane hydrocarbons) were not seen in this order in any other packaging material investigated making this products identification unique. It should be noted that this technique is excellent for differentiating between contact packaging products as each displayed unique fingerprints. Static headspace analysis permits the analysis of the trace surface components making this unique distinction possible. The trapping module of the HT3 was not utilized for this investigation. Further studies are underway using dynamic headspace analysis as it offers significantly lower levels of detection. Using the method parameters in this presentation the identification of VOC contaminants is possible through static headspace analysis. The SCION Instruments headspace system allows for unattended operation and no sample preparation. The Method Optimization Mode (M.O.M) has many advantages as no sample preparation is needed. The HT3 is capable of switching between both static and dynamic modes within a single schedule enabling both low and high level component analysis.

ORDER INFORMATION

Download the Application Note

Download our full Application Note: Headspace Analysis of Volatile Organic Compounds (VOC’s) in Contact Packaging Materials using the HT3 Automated Headspace Analyser

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, follow us on social media and sign up to our newsletter below.