A Guide to Analytical Method Validation

Why is analytical method validation important?

Analytical method validation is important across many different industries including, pharmaceutical, environmental, food and chemical manufacturing. Method validation aims to ensure that the analytical assays used are accurate, precise, reliable and suitable for their intended purpose.

Even when method validation is not required it is still useful to partially validate your analytical method to ensure the method is reliable.

Method specificity

The specificity is the ability of a method to measure both accurately and specifically the analyte of interest when in the presence of other interferences that may be present in the sample matrix.

Method selectivity

Selectivity describes the degree to which the method is able to quantify an analyte in the presence of other target analytes or matrix interferences. It would not be practical to study every possible interference therefore, it is best to identify the most likely and worst interferences.

Linearity and Range

For a method to be successfully validated it must be able to give results that are proportional to analyte concentration within a given range.

The linearity should be demonstrated across the entire range of the analytical procedure, usually a minimum of five concentration points is suggested.

Limit of detection

The limit of detection (LOD) can be defined by running samples of a known concentration to determine the lowest concentration of analyte which can be reliably detected. Confidence levels for LOD are generally 3×signal/noise level.

Limit of quantification

The limit of quantification (LOQ) is the lowest concentration of analyte that can be reliably quantified, with acceptable precision and accuracy. For LOQs the confidence level is generally 10×signal/noise level. See our guide on accuracy and precision for more information.

System suitability testing

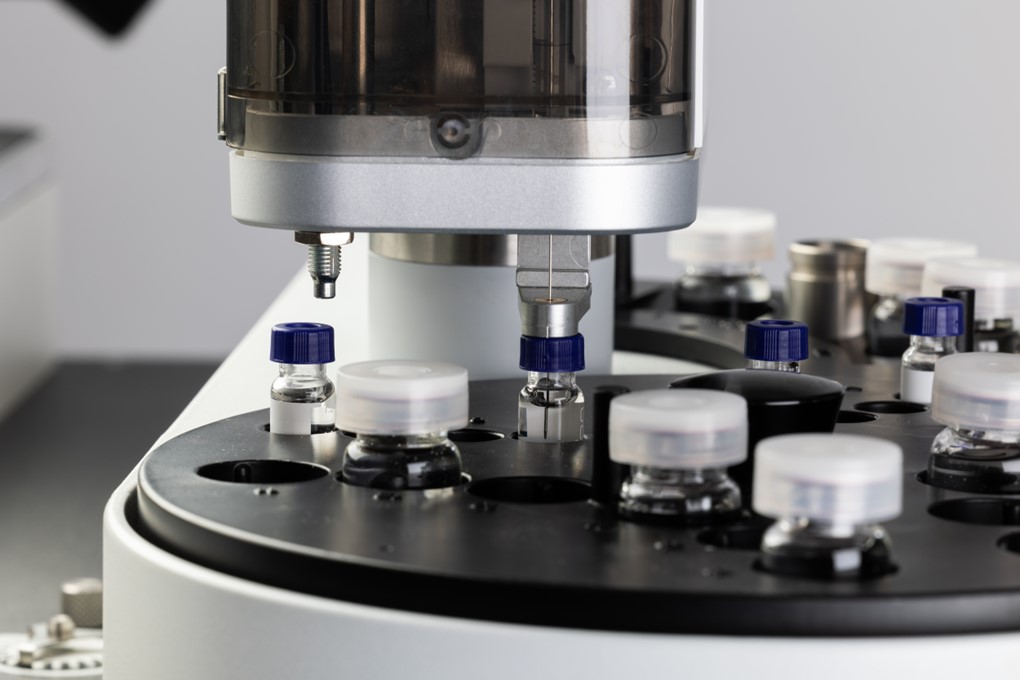

System suitability testing ensures system performance both before and after the testing of unknowns. They are used to test both the resolution and reproducibility of the system.

Method validation tools

Blank samples can be used to assess the measured signal and how much the analyte is contributing to the signal and what contributions are coming from outside sources.

There are two main types of blank samples a reagent blank and a matrix blank. Reagent blanks are composed of reagents that are used during the extraction procedure. The other type of blank is the matrix blank which is essentially the sample matrix with no analyte present within the sample.

Spiked solutions can be of use during method validation; they are solutions that have been spiked with a known concentration of analyte – this enables the response to be measured and then calculated in terms of the amount of analyte added. Spiking samples also allows us to calculate the analyte recovery which gives us confidence in the analytical method as well as our sample preparation method.

Reference materials may also be of use during method validation.

Method validation requirements

When validating an analytical method it is important to understand the application that the method will be used for. This often determines the validation requirements of a particular assay, for example methods that are intend for the analysis of pharmaceutical compounds will have more stringent validation requirements than those intended for the analysis of e.g. paints and cleaning products.