PFPD guide

Pulsed Flame Photometric Detector (PFPD), has a photomultiplier which looks at a flame within the detector. The signal is acquired from changes in colour of the flame. Each element has its own emission wavelength or colour (fluorescence). Band Pass Optical Filters are used to control which element is measured by filtering out light from other sources. The light from elemental emission is detected.

How does the detector work ?

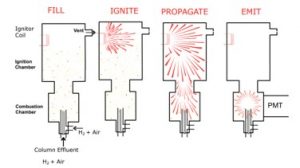

A pulsed flame allows to selective amplification of element-specific emissions whilst minimising background noise which is impossible with a constant flame because all emissions are continuous. This means it is not possible to detect each emission individually. With the pulsed flame, the combustion of the elemental species lasts a lot longer than that of hydrocarbons and interferences. Once elemental combustion is complete, the flame will be extinguished then another flame is established to measure the next data point. The ON and OFF is called ‘pulsing’. The operation of a pulsed flame is detailed below and can be seen in Figure 1.

- Fill: Combustible gas mixture fills the detector. The flame is OFF but the photomultiplier is ON and collecting, waiting for enough fuel for ignition to start.

- Ignite: there is enough hydrogen and air in the ignition chamber to start a flame. Detection of ignition will start a gate delay timer.

- Propagate: the flame moves to all the chambers which will combust the hydrocarbons and hydrogen. During this time the gate delay is active and the photomultiplier is not collecting data.

- Emit: As compounds elute they undergo combustion where excited species will fluoresce. The gate width is active and the photomultiplier is collecting the selected emission data.This complete cycle takes around 300 milliseconds, and will repeat. You will hear a Tick-Tock sound every time this happens.

Figure 1 Stages of pulsed flame operation

PFPD modes

The Phosphorus/Sulfur (P/S) mode is the most commonly used configuration and designed to detect phosphorus and sulfur compounds. During the combustion, these elements emit light at characteristic wavelengths, which can be filtered to minimize interference.

To improve selectivity and sensitivity the use of different optical filters for different elements are employed. A blue filter is usually used while measuring in P/S mode and a red filter in N mode.

Figure 2 PFPD band pass optical filters

For nitrogen (N) we use a different photomultiplier because photomultipliers are affected by heat. To reduce this impact, a quartz light pipe is used which will transmit the light from the chamber to the multiplier. The nitrogen containing compounds are converted into nitric oxide (NO) during combustion. The NO reacts with hydrogen which remains in the combustor after the flame extinguishes, this produces HNO. The photomultiplier will detect the released energy from the light.

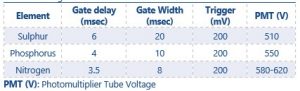

Suggested settings

The PFPD should be ‘tuned’ before usage. For a more in depth guide on how to tune the detector please refer to the user manual. The adjustment settings displayed in Table 1 are recommended for the setup of the PFPD and routine operation.