Transformer Oil Gas Analysis via Stripper Column (ASTM D3612)

Introduction

Insulating fluids, generally mineral oils, are used in transformers. Under normal, mild conditions, there is very little decomposition. However, occasionally localised or general heating of the oil occurs, and decomposition products are formed. If the concentration of these gases reach a critical point, the chances of catastrophic transformer failure are high. ASTM D3612 describes in detail three different routes for transformer gas analysis.

During Vacuum Extraction gases are extracted from the oil via a vacuum extraction device and analysed using gas chromatography (GC). Stripper Column Extraction details the extraction of dissolved gases from a sample of oil by sparging the oil with the carrier gas, onto a stripper column containing a high surface area bead. The gases are then flushed from the stripper column into a GC for analysis. The final method is Headspace Sampling in which an oil sample is brought into contact with the headspace in a closed vessel sparged with argon. As a result, a portion of gas dissolved in the oil is transferred to the headspace. This application note describes the second method; Stripper Column analysis.

Experimental

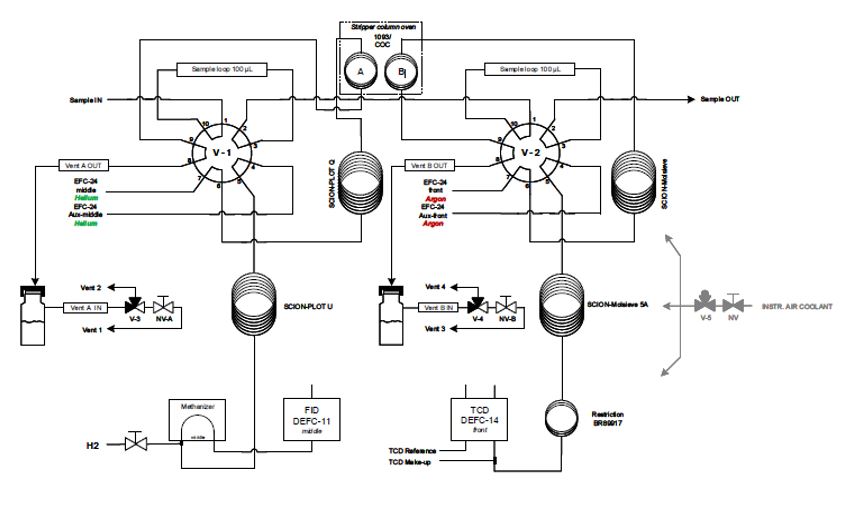

The SCION TOGA Analyser comprised of a SCION 456 GC with FID and TCD detectors. A headspace sampler in sample loop mode was also used. Figure 1 details the schematic overview of the TOGA Analyser.

Figure 1. Schematic operation of the TOGA Analysis

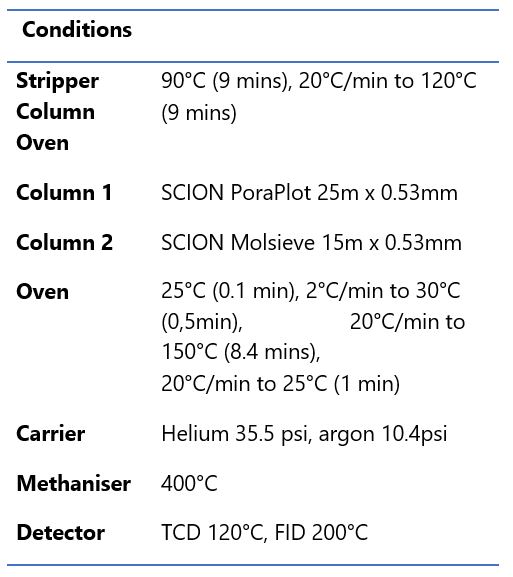

The system was equipped with luer lock connections for easy operation. The TOGA syringe infusion pump was used to introduce the oil sample to the TOGA analyser. Table 1 details the analytical parameters of the TOGA Analyser.

Table 1. Analytical conditions of the TOGA Analyser

Results

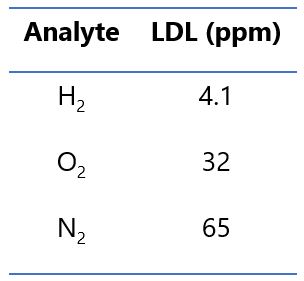

A low concentration reference standard gas mixture was used to calibrate the system. Table 2 details the LDL levels of hydrogen, oxygen and nitrogen.

Table 2. Calculated LDL

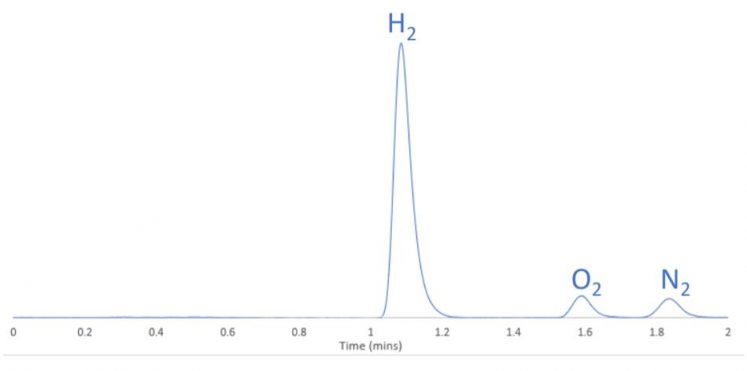

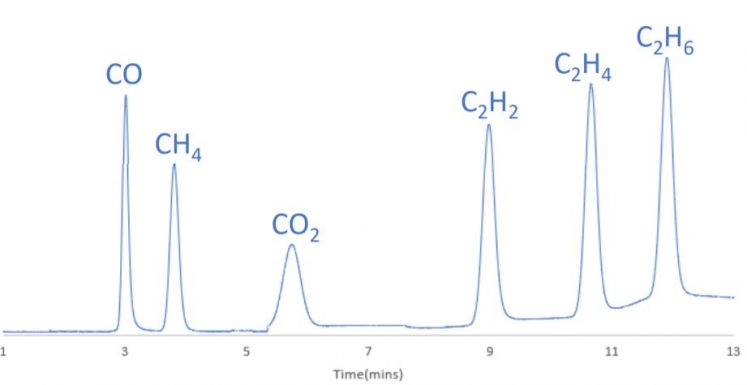

The LDL figures were compliant with the specifications of the ASTM method. Through the use of a syringe infusion pump, the oil sample is injected via two, ten port valves, each equipped with sample loops connected to the stripper columns. Each stripper column extracts the dissolved gases containing in the oil and passes them to two separate channels for analysis. One channel is equipped with two Molsieve 5 columns using argon as the carrier gas. The column is optimised to separate lighter gases such as hydrogen, oxygen and nitrogen. The other channel is equipped with a PoraPlot columns, with helium as the carrier gas. This channel is used to separate carbon gases including carbon dioxide and carbon monoxide. Figure 2 shows the TCD channel of the TOGA analyser whereas Figure 3 shows the FID channel.

Fig 2. Oil sample; TCD channel

Fig 3. Oil sample; FID channel

A methaniser is used in combination with the FID so that the carbon gases are converted to hydrocarbons, which enables them to be detected a low level ppm. The use of argon as one of the carrier gases ensures that the best detection levels for hydrogen are obtained whilst still providing satisfactory detection levels for both oxygen and nitrogen.

Once the extraction of the oil has been completed, all remaining components (of no interest) are back flushed and vented. The components of interest in the extracted gas are H2, O2, N2, CO, CO2, methane, ethane, ethylene, acetylene, propane and propylene.

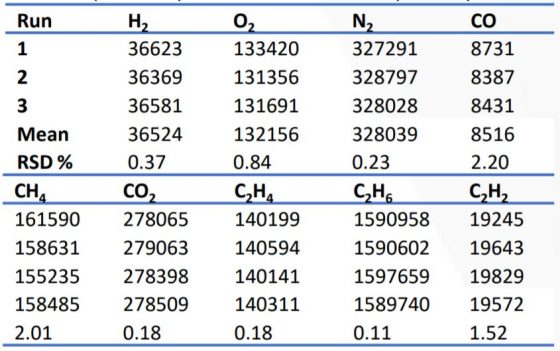

Repeatability resting was performed using three injections of the same sample. The peak areas obtained from the analysis are summarised in Table 3. Also shown are the corresponding concentrations. The repeatability values shown are well in line with those specified in the ASTM method. It is important to note that the component peak shapes are significantly better when the gases are analysed directly using GC than when the stripper method is used. This is due to the interaction of the dissolved gases with the stripper column and the length of time it takes for the gases to evaporate and move on to the analytical columns.

Table 3. Repeatability values from the oil sample analysis

Conclusion

Full separation of all components of interest with easy and reliable quantification results in very good repeatability using the SCION Transformer Gas Oil Analyser. The analysis of dissolved gases in transformer oil according to ASTM D3612, method C, can also be performed perfectly with the SCION TOGA analyser with stripper columns.

Download Application Note

Download the complete Application Note: Transformer Oil Gas Analysis via Stripper Column (ASTM D3612)

SCION Gas Chromatography Analyser

A SCION Gas Chromatography Analyser was used to conduct this research. Providing excellent solutions for Environmental, Oil and Gas and Chemical industries, find out more about Scion GC Analysers.

If you would like to speak to a member of our team for more information, please don’t hesitate to get in touch. Or to stay in the loop regarding future research and articles from SCION Instruments, why not join us on social media and sign up to our eNewsletter today?