Thermal Conductivity Detector - Gas Chromatography

Thermal Conductivity Detector – Gas Chromatography

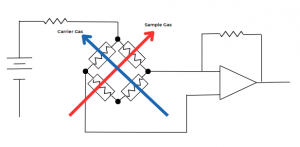

The Thermal Conductivity Detector (TCD) stands as one of the earliest detectors employed in Gas Chromatography (GC) for the detection and quantification of components within a gas sample. Its operational principle hinges on the distinction in thermal conductivities among various gases. The following outlines the step-by-step functionality of the TCD, and Figure 1 provides a visual representation of the detector for enhanced comprehension.

Figure 1. Scheme of the TCD

The TCD comprises a thermal conductivity cell, typically a compact metal or ceramic block housing a filament or wire coil. Initially, the thermal conductivity cell is brought to a state of thermal equilibrium, where both the filament and the surrounding material attain a stable temperature. Subsequently, the sample gas, segregated by the gas chromatograph, is introduced into the TCD. The sample gas traverses the filament or wire coil within the thermal conductivity cell, impacting the heat transfer between the filament and the surrounding material. The diverse components of the sample, as they pass over the filament, induce alterations in the thermal conductivity of the gas within the TCD cell, leading to temperature fluctuations in the filament.

Additionally, the TCD is an integral part of a bridge circuit. The temperature variations in the filament create an imbalance in the bridge circuit. To uphold the bridge circuit in a balanced state, a current is directed through the filament to restore its temperature to the equilibrium state. The quantity of current necessary to achieve this equilibrium directly corresponds to the thermal conductivity of the sample gas. The current needed to sustain the temperature balance in the filament is measured, converted into an electrical signal, amplified, and then recorded by the data system. The magnitude of the signal is proportionate to the concentration of the analyte in the sample gas.

The Thermal Conductivity Detector, although not as sensitive as some alternative detectors, is non-destructive and versatile. It finds utility across a broad spectrum of compounds, making it adept at detecting gases with comparable thermal conductivities. Its robust nature makes it widely applicable, particularly in scenarios where its adaptability proves advantageous, such as the analysis of permanent gases or in situations where a flame-based detector may be unsuitable.

Consumable and Spares

Spares:

The Thermal Conductivity Detector (TCD) is not user serviceable and has no replacement parts. To condition the TCD, set the detector temperature to 350 °C and allow it condition for 4 hours or overnight. The Electronics (filaments) box must be Unchecked (switched OFF) during this procedure.

Consumables:

| 41312148 | 15% GRAPHITE/85% VESPEL FERRULE 1/16″ WITH 0.4MM HOLE PK/10 |

| 41312149 | 15% GRAPHITE/85% VESPEL FERRULE 1/16″ WITH 0.5MM HOLE PK/10 |

| 41312150 | 15% GRAPHITE/85% VESPEL FERRULE 1/16″ WITH 0.8MM HOLE PK/10 |

| 41312153 | 15% GRAPHITE/85% VESPEL FERRULE 1/16″ NO HOLE PK/10 |

Order Today

For more information or to place an order, please get in touch.