IP480 Determination of Boiling Range Distribution of Middle Distillates and Lubricating Base Oils - Gas Chromatography Method

Standardized method IP480 describes the determination of boiling range distribution of distillates and lubricating base oils by gas chromatography, with initial boiling points (IBP) of at least 100°C and final boiling points (FBP) of below 750°C (C120). SCION Instruments offers the solution for a simulated distillation of middle distillates and lubricating base oils.

Simulated Gas chromatography distillations can be used as a reference method for conventional distillation methods which can provide a quantitive percent mass yield as a function of the boiling point for hydrocarbon components in the sample. The boiling point distribution is a routinely used parameter to monitor and improve the refinery production process. Simulated distillations are a safer and faster way to perform an similar boiling range distribution of distillates.

This SIMDIST application is applicable on the SCION Instruments 8300 GC or 8500 GC-platform, shown in figure 1.

Figure 1. SCION Instruments GC platform equipped with the 8400PRO autosampler.

RESULTS AND DISCUSSION

In this application note a SCION Instruments 8X00-GC is used, equipped with a temperature programmable air cold on column (COC) injector with air cooling, a SCION-Simdist column for excellent separation of the hydrocarbons, and a high temperature (HT) Flame Ionization Detector (FID) with ceramic HT flame tip. For good reproducibility results a 8400PRO autosampler is used.

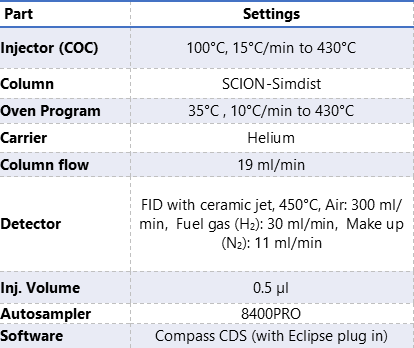

Table 1 is showing the analytical conditions of the SCION Instruments GC system.

Table 1. Analytical conditions

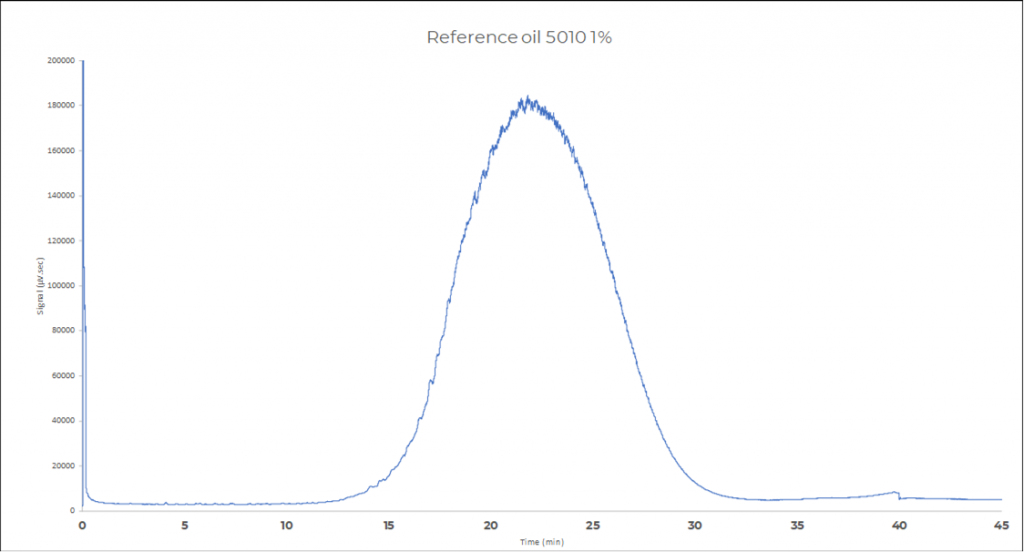

Reference oil 5010 1%

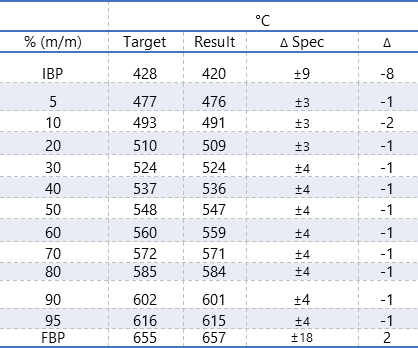

A reference oil with known initial boiling point and final boiling point is injected to validate the method and system. See figure 2 and table 2 for the results and specifications of the reference oil. In figure 2, point 1 is the start of elution time, point 2 the initial boiling point (IBP), point 3 final boiling point (FBP) and point 4 is the end of elution of the sample. Septum purge is opened after elution of the sample for flushing the injector. The results in table 2 show that all targets mentioned in IP480 are easily achieved.

Table 2. Results Reference oil 5010 1%

Figure 2. Chromatogram Reference Oil 5010 1%

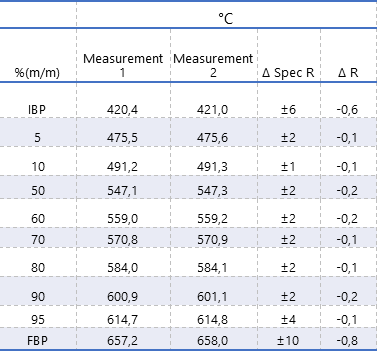

Repeatability (R) is determined by measuring the reference oil 5010 1% in duplicate. The difference (Δ) between the 2 generated boiling point distributions is calculated and compared with the set specification mentioned in IP480. According to table 3 the system is easily achieving good repeatability results within specifications.

Table 3. Repeatability (R) results

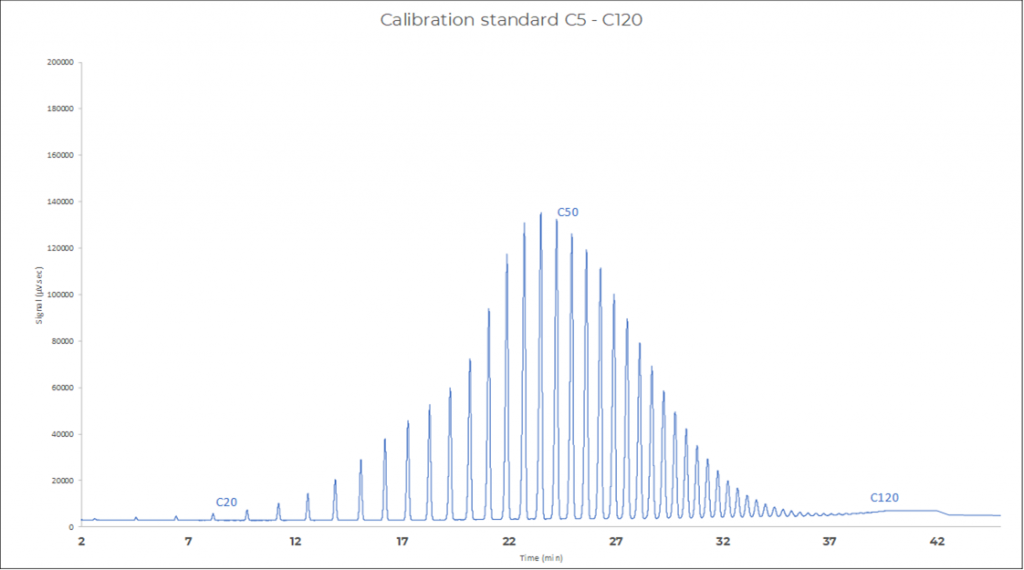

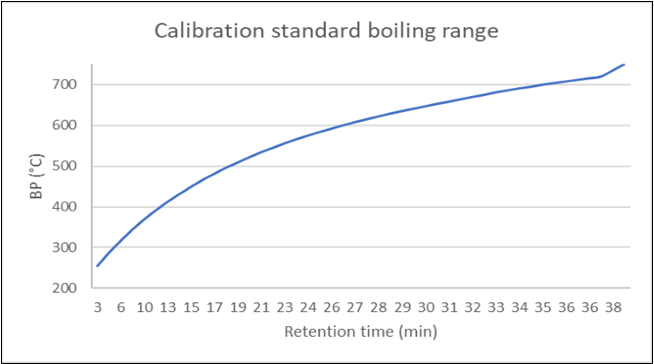

The relation between the boiling point versus retention time is determined by injecting a calibration mixture, covering the range from C5 up to C120, dissolved in carbon disulfide. See figure 3 for the chromatogram of the calibration standard and figure 4 for the retention time vs. boiling point of the calibration standard.

The relation between the boiling point versus retention time is determined by injecting a calibration mixture, covering the range from C5 up to C120, dissolved in carbon disulfide. See figure 3 for the chromatogram of the calibration standard and figure 4 for the retention time vs. boiling point of the calibration standard.

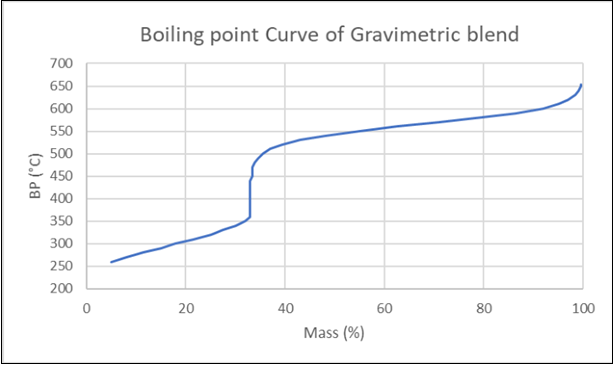

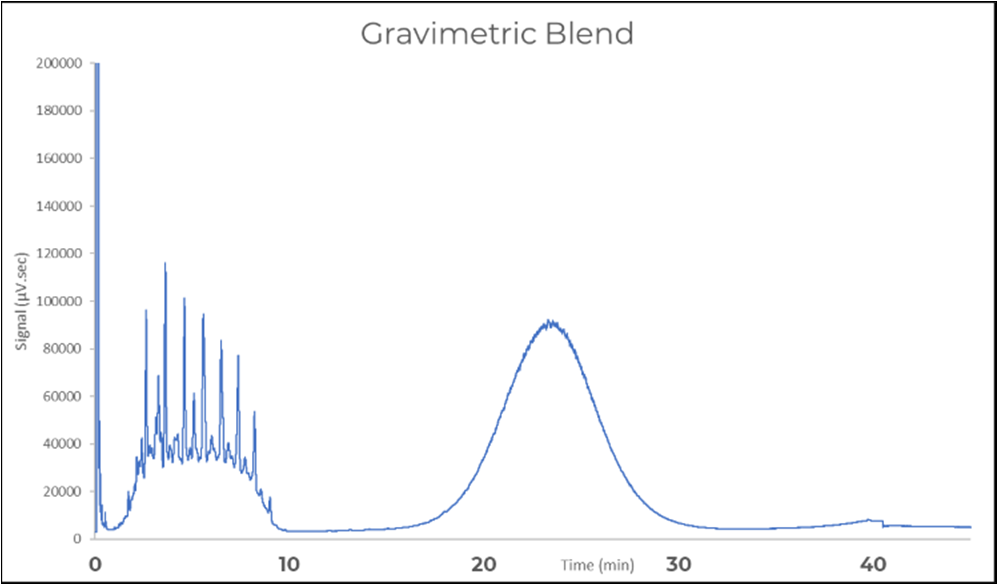

A gravimetric blend is analysed for checking the relative response of the two distillates and to check the baselines at the start, middle and end of the chromatogram. Figure 6 shows the chromatogram of analysis of the gravimetric blend, where a baseline separation is shown between the two peaks. Figure 6 is showing the boiling point curve vs. mass % of the gravimetric blend.

Figure 3. Chromatogram Calibration mix

Figure 4. Retention time (RT) vs. boiling point

Figure 5. Chromatogram Gravimetric Blend

Figure 6. Boiling point curve of the Gravimetric Blend

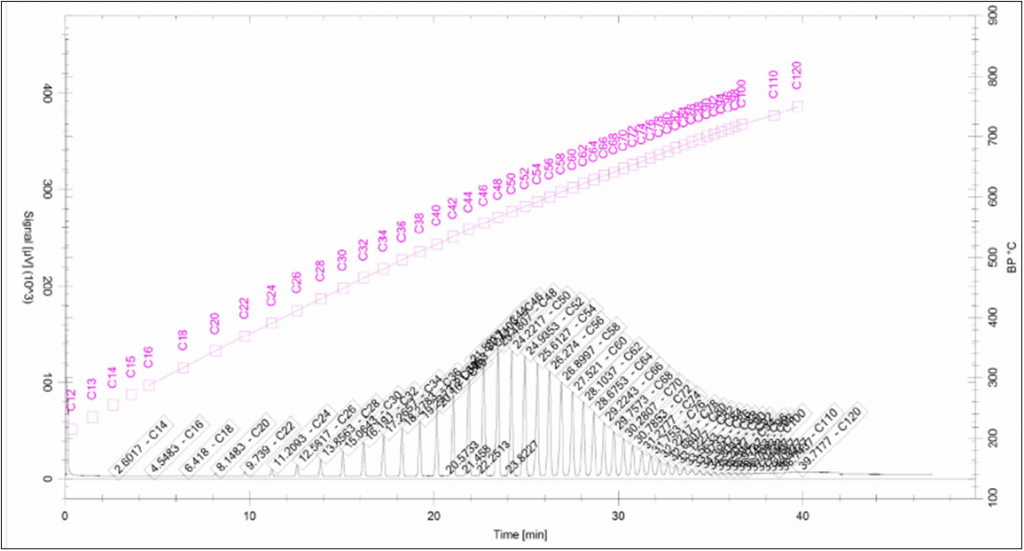

Figure 7 is showing a chromatogram using the Compass Eclipse software plug in, with combined Retention time vs boiling point curve. The software makes it also possible to calculate the analysis with different standardized methods.

Figure 7. Chromatogram calibration mix using the compass Eclipse software plug in, and other optional methods.

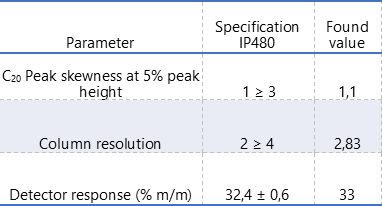

System performance check was generated from the calibration mix chromatogram and the gravimetric blend was used to obtain the detector response. The results are shown in table 4. All results do meet up to the specifications set up in standardized method IP480.

For the detector response the mass % of the first fraction of the gravimetric blend should be 32.4% (±0.6%) at a BP 400°C, is easily achieved with a mass of 33%. This result is also shown in figure 6.

Table 4. System performance results

CONCLUSION

The SCION Instruments 8500 GC and 8300 GC-platforms provide a robust and complete solution for the simulated distillation of distillates and lubricating base oils, following standardized method IP480. The obtained results demonstrate that this method and the SCION Instruments GC system configuration performs excellent and meets all the specifications mentioned in IP480.

The equipment of the 8500 GC and 8300 GC analyzer is pre determined, for ordering information or customisation please contact your local sales representative.

Although the 4X6-GC series is not shown in this application note, it is also possible to perform this method on the SCION instruments 4X6 GC series.

Download the Application Note on IP480 Determination

Download our full Application Note: IP480 Determination of boiling range distribution of middle distillates and lubricating base oils – Gas chromatography method

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, follow us on social media and sign up to our newsletter below.