SCION Instruments Gas Chromatography Injectors

What are injectors?

The injector is a heated or cold chamber with a glass liner. The glass liner is an inert glass tube which prevents active sites and helps focus the sample onto the column. A sample which can be either liquid or gas is manually or automatically injected through a septum into the injector. Heated injectors vaporize liquid samples and mix it with the carrier gas before it enters the column. The carrier gas flow is crucial as this helps transferring the vaporized sample into the column efficiently.

GC injector techniques

The sample injection techniques varies between the various injector types.

Split Injection: this technique is often used for samples with high concentrations. The sample is split so only a small part will enter the column while the rest is vented out of the instrument. This prevents overloading the column and detector.

Splitless Injection: this technique is used for trace analysis. The entire sample will enter the column and therefore help to achieve sensitivity of low concentration analytes, however matrix effects may be more prominent.Temperature programable injection: can be used for more complex and heat sensitive samples. Uses a precise temperature controlled method in the injector, which is programmable to change during the injection process.

On-Column Injection: is often used with packed columns. The sample is injected directly onto the column.

Choosing the correct injection technique can significantly affect the quality of the sample results. Optimised injection ensures that the sample is introduced correctly leading to better sensitivity and more accurate results.

Split/Splitless Injector

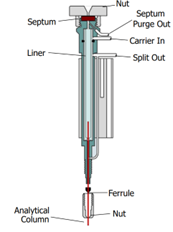

The SCION Instruments Split/Splitless (SSL) injector shown in Figure 1, is designed to operate in two modes; split and splitless, which can be programmed in the instrument method.

A split/splitless program allows customers to work with a wide range of sample concentrations. Within CompassCDS, you can easily switch between the two modes based on the concentration of the samples.

The injector is isothermal, so it can only be programmed to one constant temperature during the analysis. This temperature is application dependant and should be set high enough to ensure that any target analytes, sample matrix, and diluent are all volatilized effectively in the injector. Capillary columns are commonly used with this injector.

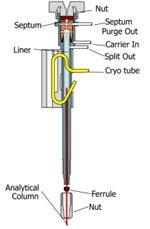

PTV injector

The Programmable Temperature Vaporizing (PTV) injector, shown in Figure 2, works in a similar manner to the SSL injector with the option to operate in split and splitless mode. The main difference is within CompassCDS, the injector can easily be set to a temperature programmable injection. The advantage of this being that the initial injection temperature can be low in order to avoid thermal decomposition of temperature sensitive compounds and then the temperature can be raised rapidly to volatilize high boiling components. This allows for simultaneous analysis of analytes in complex samples.

In addition, a cooling option can be added to help speed up the cool down time between injections, or for low temperature injections. Depending on the analysis there are several cooling options to pick from: Air, LN2 and LCO2.

Splitless Injection

A splitless injection is typically used for trace analysis. During the analysis the split vent is closed which means that all of the sample will enter the column and be detected. This can greatly increase sensitivity.

Care should be taken with higher concentration samples as the column and detector can become overloaded, leading to poor results and contamination.

It is also important to note that using this technique may also increase interference from the sample matrix.

See our method development guide technical note for hints and tips on good method development.

Splitless time

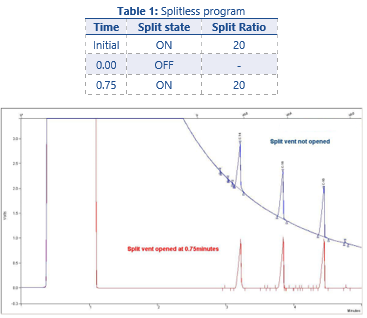

A useful technique to consider when performing splitless injections is “splitless time”. Splitless time is where the split vent is closed at the point of injection and then opened after a short time. In this example (Figure 3), the split is turned ON at 0.75 minutes and the first sample peak arrives at 3 minutes. Setting the split to ON at 0.75 minutes ensures that the baseline is stable before the sample peaks appear. This technique can help prevent overloading the column and can reduce tailing of the solvent and sample peaks. Table 1 shows an example splitless program.

Figure 3: Splitless time comparison

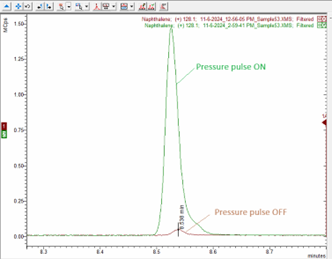

Pressure pulse

Using pressure pulse is only possible in constant flow mode. The pressure pulse increases the pressure for set time during the initial analysis, resulting in more sample on the column and less sample loss in the injector. This increases the overall sensitivity. The pressure pulse is usually set between 25 and 40 psi and for a shorter duration than the splitless program time, typically between 0.25 and 0.50 minutes. However, this can vary depending on the application. Pressure pulse is typically used when working with an MS detector.

Split injection

Split injections are used for high concentration samples. A “split ratio” typically is set between 10:1 and 100:1. The split volume is then determined by the carrier flow. For example, with a carrier gas flow of 1.5 mL/min and the split set to 10:1 then 15 mL/min will be vented thus reducing the sample concentration onto the column by 10. High split ratios are used for highly-concentrated samples to prevent column overload, while lower split ratios are used for more sensitive analyses. Understanding and setting the correct split ratio is required for optimizing the best possible results for the analysis.

Figure 4 shows a comparison of an analytical standard injected on a split (10:1) method and a pulsed splitless injection. This highlights the importance of choice of injection technique.

Figure 4: Overlay of chromatograms of split 10:1 (red) and pulsed splitless (green)

Liner choice

Choosing the correct liner is crucial because it facilitates the transfer of the sample to the GC column. It can significantly influence the accuracy of the analysis. At SCION Instruments, we have various different liner types available. Learn more about liners on our website: GC Liner Selection Guide | Inlet Liners | SCION Instruments.

Why should you choose the SCION Instruments Split/Splitless injectors?

– Effectively it keeps the heat away from the injector nut and septum.

– Dual split points, allowing for a more homogenous split.

– Provides cleaner chromatography, more reproducible results and a longer consumable life.