FID Maintenance Guide

What is a flame ionization detector?

A flame ionization detector (FID) is a common detector used within a gas chromatograph (GC) for the detection of organic compounds. It is a sensitive detector which can be used for the identification and quantification of a diverse range of organic compounds across many industries.

An FID uses a flame fuelled by hydrogen and air to ionize the carbon atoms in the organic compounds after they have been separated by a GC column. The ions are collected and measured by the detector’s electrodes and the current is converted into electrical signal which is reported in picoamperes (pA) or millivolts (mV).

Preparation for FID maintenance

The frequency of the FID maintenance is dependent upon the sample matrix and application your laboratory is conducting. It is best practice to have a maintenance schedule and log in place within your lab.

Before maintenance can begin on the FID it is important to do the following steps:

- Turn off all instrument gases and FID electronics

- Cool down the FID to room temperature

- Uninstall the column

Once these steps have been completed then the FID can be handled and disassembly can begin.

Figure 1: FID expanded to show full assembly of FID.

Figure 1 shows an expanded FID to show the parts and consumables in the detector. This can be used to assist in the maintenance of the FID. It is crucial that training is provided for

all users which will be conducting maintenance on the FID.

FID consumables

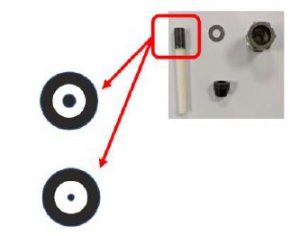

The most commonly changed parts of the FID consumables are the FlameTip ferrule and aluminium washer. It is key to ensure that the FlameTip ferrule being used is suitable for the detector temperature in your method. An 85% Vespel/ 15% graphite ferrule will have a limit of 350 °C whereas a 100% graphite ferrule allows for high temperature applications up to 450 °C. Figure 2 shows an example of a FlameTip ferrule and the aluminium washer.

FID FlameTip

There are two FlameTip types (see Figure 2):

- 0.02” jet for use with packed or capillary columns

- 0.01” jet for use with capillary columns

The 0.01” jet gives more sensitivity but is prone to blockages. As part of FID maintenance check the FlameTip is clear from debris and not blocked. If the FlameTip is damaged or blocked, it can be replaced. Take care when handling the FlameTip as it is ceramic so can be easily broken.

Figure 2: Two sizes of FlameTip and the FlameTip ferrule, aluminium washer and nut which connects to detector base.

After FID maintenance

Once maintenance has been performed on the FID and reassembled, the column can be reinstalled, electronics and gases turned on and the FID brought back up to method

temperature. If noise is high then leave the FID at or slightly above operating temperature until signal stabilises.

If problems with the FID persist after maintenance where consumables have been changed, contact service for further assistance.