SCION Compass Chromatography Data System CDS Overview

A Chromatography Data System (CDS) plays a pivotal role in instrument control, data processing, report generation and data archiving. It is essential for Chromatographic Analysis, including high-performance liquid chromatography (HPLC), gas chromatography (GC), ion chromatography (IC), supercritical fluid chromatography (SFC), and capillary electrophoresis (CE), ultra-high performance liquid chromatography (UHPLC), tandem techniques such as GC-GC, GC-MS, LC-GC, LC-MS, which constitutes a major portion of testing performed in analytical laboratories.

What is a Chromatography Data System?

A chromatography data system (CDS), which is also sometimes referred to as a chromatography data management system (CDMS), is a set of dedicated data-collection tools that integrate with a laboratory’s chromatography equipment. A base CDS will set up a desired methodology to be used by the chromatography equipment, acquire data from it, process the acquired data, store the information in a database, or in a file manager structure, and interface with other laboratory informatics systems to import and export files and data.

A chromatography data system (CDS) is beneficial because it automates the collection of data, allowing analysts to perform tasks without having to manually manage datasets, reducing user-error and ensuring that the information is as robust as possible. An advanced CDS will also ensure that laboratory workflows and practices meet the strict regulatory standards that surround data integrity. Chromatography labs must currently be able to provide relevant data trails for auditing while adhering to increasing regulations. Attempting to manually collect and report data without a robust system in place, however, can rapidly become complicated and open to error, requiring the use of advanced software systems in modern labs.

In laboratories performing regulated testing for quality control, pharmaceutical development, or manufacturing, the CDS is likely a validated client-server network designed to provide data security and integrity.

How does a CDS Work?

Laboratory scientists often spend as much time performing data processing as in front of a chromatographic system. Therefore, it is critical to have an in-depth knowledge of the role of a CDS in both instrument control and data processing to have a better understanding of improved and more efficient analytical practices.

A modern CDS is a complex software system that is used in many rapidly changing analytical science fields to control instruments, gather and process data, and generate reports.

A CDS may be set up for use in three primary ways:

- As a standalone system that controls two or more chromatographs

- As a standalone system that controls a single chromatograph, including LC-MS or GC-MS instruments

- As a networked system that controls multiple instruments in one or more labs.

The requirements and functionalities of a modern CDS network for regulated laboratories include:

- Data acquisition

- Data processing

- Instrument Control

- Regulatory compliance

Furthermore, the following desirable characteristics can be incorporated into CDS networks:

- Multi-vendor, multi-instrument, multi-lab, multi-detector and multi-language connectivity

- Networking and Operating System

- Data security, flexibility and archival

- Other enhancements and links to informatics systems

The Role of a Chromatography Data System

Chromatography data systems are increasingly being used in the automation of the analytical workflow and play a critical role in post-analysis processes.

Performing regulated HPLC release testing of a pharmaceutical sample requires considerable resource allocation for regulatory compliance in the laboratory. Furthermore, a significant amount of time and energy is required for equipment validation, personnel training, and method validation. The laboratory must also adhere to internal quality processes and standard operating procedures (SOP).

The many steps involved in chromatographic analysis workflow in a regulated laboratory make it a complex process. The analytical workflow starts with sampling, and sample/reference/mobile phase preparation before transporting the samples for analytical testing. This involves instrument and sample sequence set up, data acquisition, result calculation and report generation. Finally, the data is reviewed by the Quality Control (QC) manager and signed-off, exported to LIMS and merged with other analytical data to generate a certificate of analysis (CoA).

Step 1: Sampling and Sample Preparation

Laboratory analysis workflow starts with sampling in order to obtain a representative sample from a batch of substance. This is then followed by preparing the sample solution, reference solutions, mobile phases and system suitability solutions that verify the system’s sensitivity, precision or peak tailing performance and ability to achieve sufficient resolution and sensitivity of all key analytes. Following this, the samples are placed in the HPLC system auto sampler tray, or manually injected if the sample rate is low. All information must be recorded appropriately for traceability in a regulatory audit. This includes date, time, sample volume, sample description, sample type (unknown, blank, standard, verification), analyst, method used, noise etc.

Step 2: Analytical Testing

The next phase is analytical testing, where the CDS plays a major role in instrument control and data processing to generate results and reports. The type of methods used include instrumental setup for the acquisition of the raw data using instrument method and sample sequence, data processing to generate results using a processing method and generation of formatted reports using a reporting method. This report is then reviewed by management and signed-off directly in the CDS, where they can often be exported automatically.

Step 3: Setup of instrument and sample sequence

For a HPLC or GC method to perform correctly, all modules must be set up properly with the correct column, mobile phases, gas flows, gas types, samples, and standards. All of these instrument parameters are typically coordinated by the CDS workstation, which allows a single-point control of all the modules. The instruments are typically connected via Serial, Ethernet or USB cables, to control and deliver an instrumental method. A CDS network allows flexibility for a user to control any instruments in the network using a client or terminal in the lab, or remotely from a PC in the office or home.

A reference standard and the external standardization technique is often used to quantitate the main components and all key analytes. A sample sequence is typically set up, indicating the names, vial positions, and injection volumes of the samples, references and blanks. Before the results from any regulated sample analysis can be accepted, the HPLC or GC system must pass acceptance criteria for system suitability testing to ascertain the readiness of the system to obtain accurate and precise results. Resolution, sensitivity, tailing factor, and retention time or area precision are common parameters to determine the suitability of the system for the chromatographic assay.

Step 4: Data Acquisition and Monitoring

The system must be prepared for analysis by purging and equilibrating the system and column to ensure that the pressure and detector baseline are stable. This can be done using the instrument controller or an adjacent PC terminal in the laboratory. This can also be carried out remotely using CDS. Following this, the sample sequence or queue is started from the CDS and the data acquisition from the detector is initiated immediately after the sample is injected. Real-time monitoring is typically used to observe the chromatographic signals for the first few injections, and monitors the pertinent system parameters to ensure the sample sequence is running as expected before moving onto other tasks.

Step 5: System Suitability Testing (SST)

The first section of the sample sequence in regulated testing is generally reserved for SST, which typically involves multiple injections of SST solutions consisting of a blank, sensitivity verification, retention marker solution and reference standards The average response factors of the reference standards must come within 2% to demonstrate the proper weighing of the reference materials. The peak area precision of the five repetitive injections should be set to <0.73% RSD to demonstrate system precision, even though most laboratories still routinely use an acceptance criterion of 2.0% RSD. The tighter criteria are more appropriate.

Sample results cannot be used or reported for regulatory testing if there is a failure to meet any of the SST criteria defined (such as resolution, sensitivity, peak tailing, precision). In this scenario, the analyst must document the results and investigate the root cause for SST failure, enforcing any remedial actions, and repeating the analysis.

Step 6: Data Processing

The next step is data processing, which commences on completion of the entire sample sequence using an approved processing method. This includes appropriate peak integration, peak identification and calibration parameters. In a CDS, information and instructions are contained in the processing method, and a new one is created during method development which can be revised later to optimise all parameters. The manual processing function in CDS is most frequently used by analysts unless the sample becomes so reproducible that reports can be generated automatically. The most desirable outcome is the data collection, instrumental method and data processing method deliver reproducible results that review and sign off is all that is needed for each sample. Developing this type of robust analytical method does take some effort, but delivers benefits on sample through put, data integrity, and confidence with minimal operator intervention or input. During the development of the processing method, the data processing step can be an interactive process, as the integration, calibration and quantitation parameters are optimised, which is particularly necessary for complex chromatograms. Therefore, it is important that the CDS records the different versions of the processing method during this procedure before the final processing method is used for reporting, as complete data traceability is a mandatory requirement for CDS.

The built-in integration algorithm of a CDS is used to transform chromatography raw data into an integrated chromatogram with peak retention time and peak area or height data.

The analyst first defines the integration start and end time, the narrowest expected peak width, the peak start threshold, and the detector noise level. The traditional integration algorithm tracks the detector baseline and looks for an increasing baseline to indicate the peak start of an emerging peak. It does so by comparing the slope of the data against a user-input threshold or slope sensitivity value. Similarly, a change from a positive to a negative slope may indicate the apex or top of a chromatographic peak. Tick marks, drawn and projected baselines can be used to visualize how the CDS integrates the raw data. Because peaks broaden with retention time under isocratic conditions, raw data points are generally “bunched” to allow the appropriate settings of the peak start thresholds.

While this traditional integration algorithm can work reasonably well for simple chromatograms, it may require substantial tuning and optimization for a complex chromatogram with many merging peaks or sloping baselines. Most CDS offer options such as “valley-to-valley,” “tangential skim,” or “baseline drop” for these situations. Most CDS offer a “manual integration” option, but regulatory agencies discourage this somewhat subjective process, which can become problematic when the integrated peak is near specification limits. In an ideal situation the data should be processed with minimal user intervention or interpretation.

Step 7: Report Generation and Data Archiving

The final step in data processing involves the generation of a report for data review, deliver to customer, release of manufacture product and archival. Usually a reporting template is used, and the final report can be customised to generate the information required by the company or regulatory agency. A final report can include sample information, peak tables, chromatograms, spectral data, and pass or fail sample status against specification. A summary report can also be created that extracts results from a group of samples and performs a calculation or statistical evaluation, to ensure the results are relevant over time and do not drift.

It is important to archive, back up and secure all raw and metadata from a CDS with a high degree of data security, traceability and integrity. Raw data cannot be deleted, over-written, or altered. The CDS reports must also be reviewed and signed-off by the designated approvers in regulating testing laboratories, using an electronic signature process. Following this, many CDS have automated exporting functions which allow the exportation of approved chromatographic data to a laboratory management system, generating an official certificate of analysis of the sample after merging data from other sources.

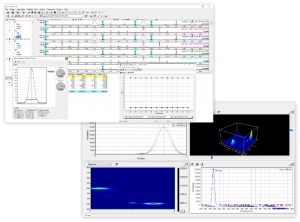

SCION’s CompassCDS

SCION Instrument’s CompassCDS is a powerful and operator friendly client/server networked chromatography data system. Developed throughout the last 20 years according to customer requirements, its capacity for customisation and intuitive, easy-to-use and information-rich user interface allows it to provide operators with a powerful tool for a variety of operations in many different analytical fields.

The CompassCDS is available as a standalone or fully networked client/server application, meeting the broadest spectrum of customer’s requirements. The product suite includes a number of industry-specific plug-in and add-on modules for specific calculation and reporting and integrates easily into existing IT environments and interfaces with LIMS, ELN, ERP (SAP) and PCS/SCADA. This facilitates, accelerates and automates data exchange, and helps to lower costs and increase the overall efficiency of the development and production process, starting from R&D over IPC to final QA/QC.

Compatibility

Our CompassCDS is compatible with and can provide support for:

SCION’s own and legacy products:

- SCION 436 and 456 GCs and Analyzers

- SCION LC6000, Uv/Vis, DAD, RI, Fluorescence detectors

- Bruker 436, 456, 430 and 450 GCs

- Varian 430, 450, 3800 and 3900 GCs

Other instrument manufacturers:

- Agilent Intuvo 8890, 9000, 7890 A/B, 7820, 6890/6850, and 5890 GCs

- Agilent 1100, 1120/1220 Compact, 1200, 1260 Infinity I, and 1260 and 1290 Infinity II LC

- Apix Analytical process GC

- CTC Pal incl. xt and RTC, RSI & LSI

- Valco Serial control valves

- Varian Star 800/850 MIB Interface (analog input, relays, RS-232, GPIB)

- Galaxie instrument control drivers, and datafiles are supported in CompassCDS, making it straightforward to upgrade from Galaxie to CompassCDS.

Find Out More

If you are interested in our CDS chromatography data system and would like to find out more information, please don’t hesitate to get in touch with a member of our team today.