Analysis of Free and Total Glycerin in B-100 Biodiesel Methyl Esters (ASTM D6584)

Introduction

The American Standard, ASTM D 6584, is the standard test method commonly used for the quantitative determination of free and total glycerin content in Fatty Acid Methyl Esters (FAME), typically intended for pure biodiesel or as a blending component for domestic and diesel fuels. Total glycerol content is calculated from the results obtained. The method is suitable for FAME from rapeseed, sunflower and soybean oils*. A metal capillary GC column was specifically used for this high temperature method. This column will not break during the extreme oven conditions and is used with a retention gap which provides both the performance and robustness required to run this application for an extended period.

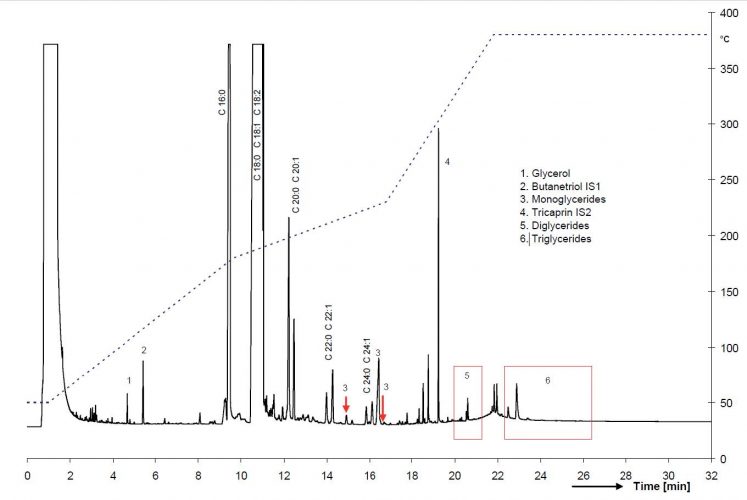

A typical chromatogram is shown in Figure 1. Biodiesel is produced by trans-esterifying the parent oil or fat with an alcohol, usually methanol, in the presence of a catalyst, usually a strong base such as sodium or potassium hydroxide, or preferably and increasingly more commonly, alkoxides. The resulting product therefore can contain not only the desired alkyl ester product but also unreacted starting material, namely TAG’s (triacylglycerides), residual alcohol, and residual catalysts. Glycerol is formed as a by-product and separated from biodiesel in the production process, however, traces thereof can be found in the final biodiesel product. Since trans-esterification is a stepwise process, MAG (monoacylglycerides) and DAG (diacylglycerides) formed as intermediates can also be found in biodiesel [Knothe, 2006].

*not suitable for FAME produced from or containing lauric oils, such as coconut and palm kernel oils, due to the problem of peak overlapping.

Fig. 1. Example chromatogram of a typical B-100 biodiesel sample made from rapeseed oil (with extra glycerol and triglycerides added) after a derivatizing reaction with MSTFA. Peaks of interest are separated from the complex matrix which consists mainly of the C18 and C16 FAMEs and other minor compounds, like sterols.

Experimental

The SCION Biodiesel analyser for ASTM D6584 is based on our 8300 GC platform, a cold on column injector, a SCION Glycerides Inert Steel analytical column with a 2m retention gap and a High Temp FID Detector. The customer has a choice between what type of cryogenic oven cooling they would like to use, either configured for liquid Carbon Dioxide or liquid Nitrogen. Analytical conditions for the ASTM D6584 analysis can be found in table 1.

|

Injector |

Cold-on-Column Start @ 100°C (1 min) 15°C/min to 370°C |

|

Column |

10m x 0.32mm x 0.10μm SCION-Glycerides Inert Steel (SC38613)

w/ Ret. Gap |

|

Oven Program |

Start @ 50°C (1 min) 15°C/min to 180°C 7°C/min to 230°C 30°C/min to 380°C

End @ 380°C hold 10 min. |

| Carrier | Helium @ 3ml/min |

| Detector | FID @ 380°C |

| Inj. Volume | 1µl |

| Software | Compass CDS |

Table 1. Analytical conditions

Sample Preparation

Standard mixtures and internal standard solutions were prepared according to the method and analysed, via the conditions denoted below, to establish the various calibration curves for the target analyses. Approximately 100 mg of sample were weighed to the nearest 0.1 mg directly in a 10 mL glass vial with septum and cap. Using a micro syringe, exactly 100 μL of each internal standard and MSTFA were added. The vials were gently shaken and allowed to equilibrate for 15 to 20 minutes at room temperature. Then, approximately 8 mL of n-Heptane was added to each vial and shaken again. Finally, 1 μL of the mixture was injected into the GC and the analysis was started (see Table 2 for typical results).

|

Index |

Name |

Area (µV.min) |

Quantity (% m/m) |

|

1 |

Monoglycerides |

14279,8 |

0,11441 |

|

2 |

Diglycerides |

1468,4 |

0,00523 |

| 3 | Triglycerides | 188,6 | 0,00358 |

| 4 | Glycerin | 30,8 | 0,00162 |

| TOTAL | 15967,6 | 0,12484 |

Table 2. Typical results for B-100 Biodiesel

Results

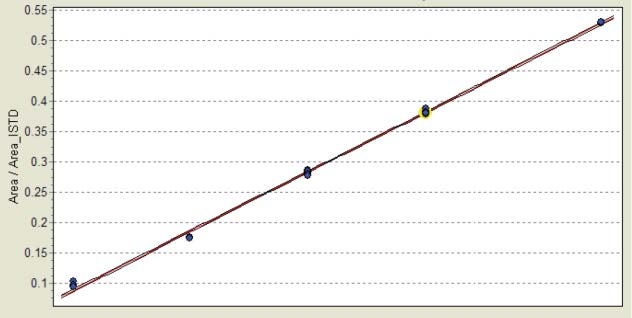

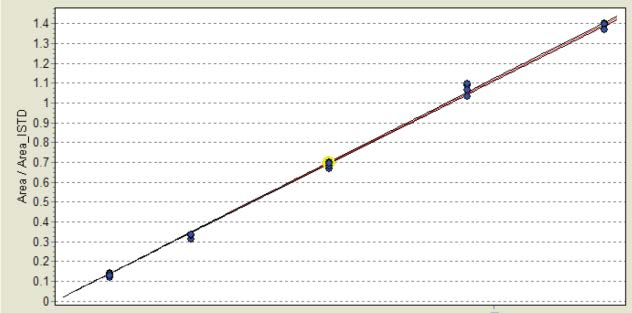

Calibration curves were obtained for glycerin, monoolein, diolein and triolein. Calibration curves for glycerin and monoolein, shown in Figures 2 and 3, are indicative of system performance for the application.

Fig. 2 Biodiesel calibration 001 Glycerin

Fig. 3 Biodiesel calibration 001 Monoolein

| File | Glycerin (% m/m) | Monoglycerides (% m/m) | Diglycerides (% m/m) | Triglycerides (% m/m) | Totals |

| 1 | 0,00162 | 0,11441 | 0,00523 | 0,00358 | 0,12484 |

| 2 | 0,00164 | 0,11167 | 0,00530 | 0,00392 | 0,12274 |

| 3 | 0,00159 | 0,10894 | 0,00519 | 0,00374 | 0,11946 |

| 4 | 0,00147 | 0,10696 | 0,00519 | 0,00359 | 0,11721 |

| 5 | 0,00161 | 0,11115 | 0,00518 | 0,00398 | 0,12192 |

| 6 | 0,00168 | 0,10720 | 0,00531 | 0,00419 | 0,11838 |

| 7 | 0,00158 | 0,10835 | 0,00524 | 0,00383 | 0,11901 |

| 8 | 0,00160 | 0,10483 | 0,00527 | 0,00388 | 0,11558 |

| 9 | 0,00156 | 0,10721 | 0,00524 | 0,00376 | 0,11777 |

| 10 | 0,00160 | 0,10731 | 0,00526 | 0,00386 | 0,11802 |

| Average | 0,001595 | 0,108803 | 0,00524 | 0,00383 | 0,11949 |

| STDEV | 5,5E-05 | 2,8E-03 | 4,5E-05 | 1,8E-04 | 2,8E-03 |

| STDEV (%) | 3,4 | 2,6 | 0,9 | 4,7 | 2,4 |

Table 3. Repeatability results for B-100 Biodiesel

Conclusion

This application note demonstrates the suitability of SCION Instruments Analyser for ASTM D6584, for the analysis of biodiesel. The calibration curves and repeatability data demonstrate good system integrity. Therefore, the system is well suited to the analysis of free and total glycerol and mono, di and triglyceride content in biodiesel in accordance with the standard method ASTM D6584.

Download Application Note

You can download the complete application note as a pdf: Analysis of Free and Total Glycerin in B-100 Biodiesel Methyl Esters (ASTM D6584)