ASTM D3612: Transformer Oil Gas Analysis via Headspace Sampling

Introduction

Insulating fluids, generally mineral oils, are used in transformers. Under normal, mild conditions, there is very little decomposition. However, occasionally localised or general heating of the oil occurs, and decomposition products are formed. If the concentration of these gases reach a critical point, the chances of catastrophic transformer oil failure are high. ASTM D3612 describes in detail three different routes for transformer gas analysis.

During Vacuum Extraction gases are extracted from the oil via a vacuum extraction device and analysed using gas chromatography (GC). Stripper Column Extraction details the extraction of dissolved gases from a sample of oil by sparging the oil with the carrier gas, onto a stripper column containing a high surface area bed. The gases are then flushed from the stripper column into a GC for analysis. The final method is Headspace Sampling in which an oil sample is brought into contact with the headspace in a closed vessel sparged with argon. As a result, a portion of gas dissolved in the oil is transferred to the headspace. This application note describes the final method; Headspace Sampling.

Experimental

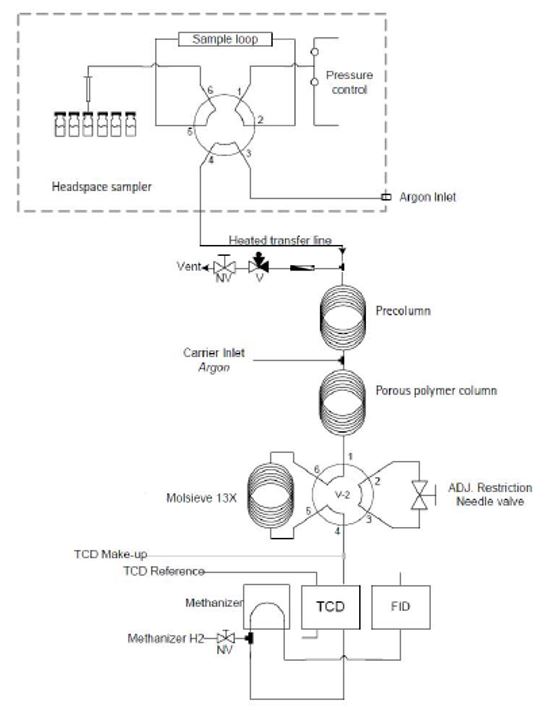

The SCION TOGA Analyser is a headspace gas chromatography system which comprised of a SCION 456 GC with FID and TCD detectors. A headspace sampler in sample loop mode was also used. Figure 1 details the schematic overview of the TOGA Analyser.

Figure 1. Schematic operation of the TOGA Analysis

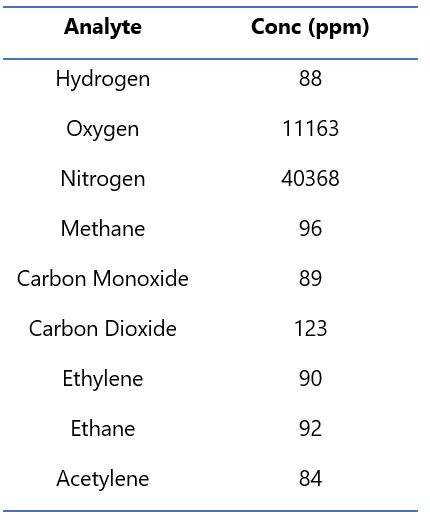

Table 1 details the analytes of interest obtained from an injection of a commercial oil standard.

Table 1. Commercial oil standard components

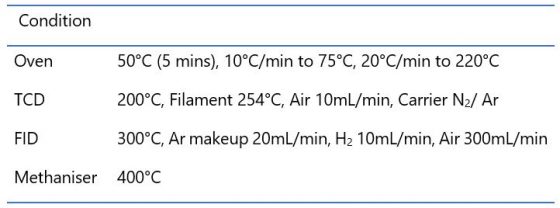

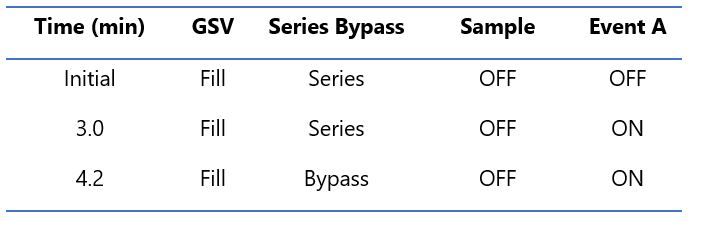

The calibration standard is carefully transferred into the headspace vial. The gases are extracted from the oil by means of a headspace autosampler and injected onto a short porous polymer precolumn and then onto a micro packed spherical carbon molecular sieve column. The fraction containing hydrogen, oxygen, nitrogen, CO and methane will elute directly from this column onto the packed SCION Molsieve column. Hydrogen, oxygen and nitrogen are detected by the TCD. CO and methane are detected by the FID, after passing the methaniser. When the molsieve column is bypassed, CO2 and the C2-C3 isomers elute from the porous polymer column and are detected by the FID (after passing through the methaniser). The back flush is set to completely elute the C3. C4+ are backflushed. Tables 2a and 2b detail the method parameters used throughout this application note.

Table 2a. Analytical conditions of the GC

Table 2b. Valve settings

Results

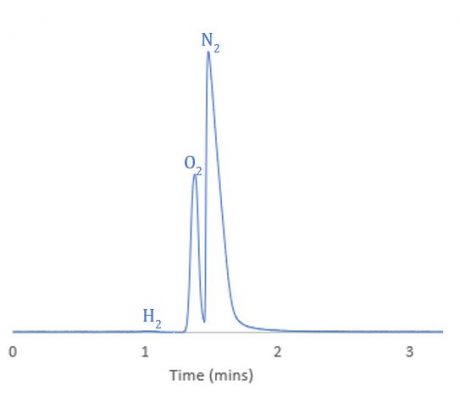

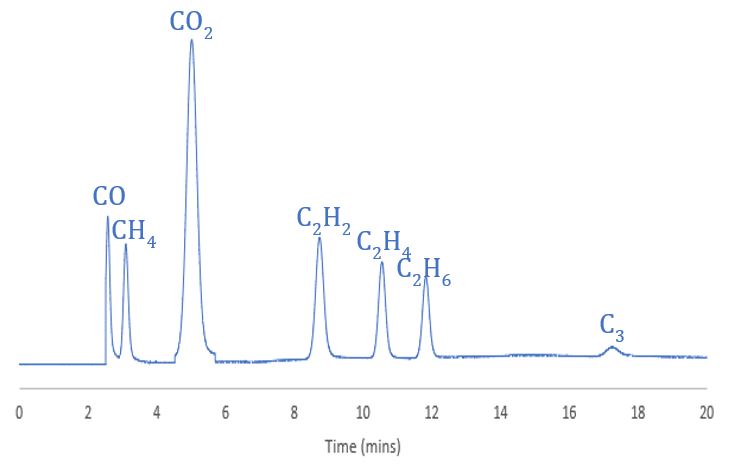

Chromatograms of both TCD and FID are shown in Figures 2 and 3.

Fig 2. TOGA Analysis; TCD channel

Fig 3. TOGA Analysis; FID channel

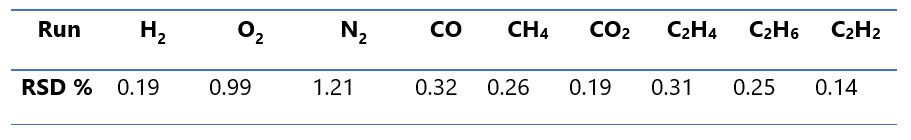

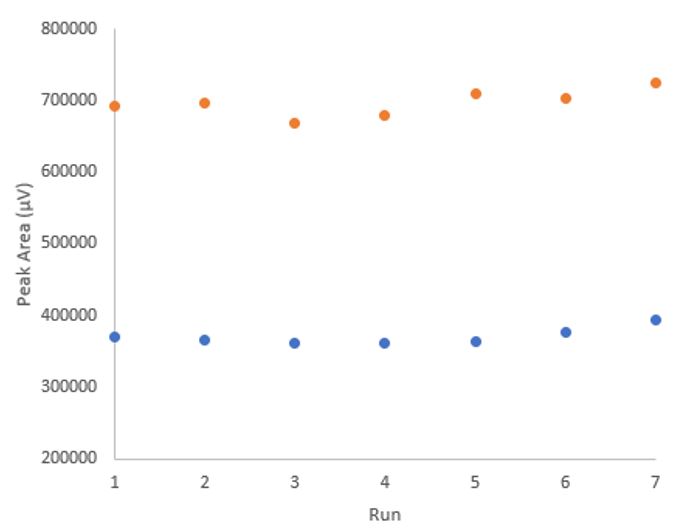

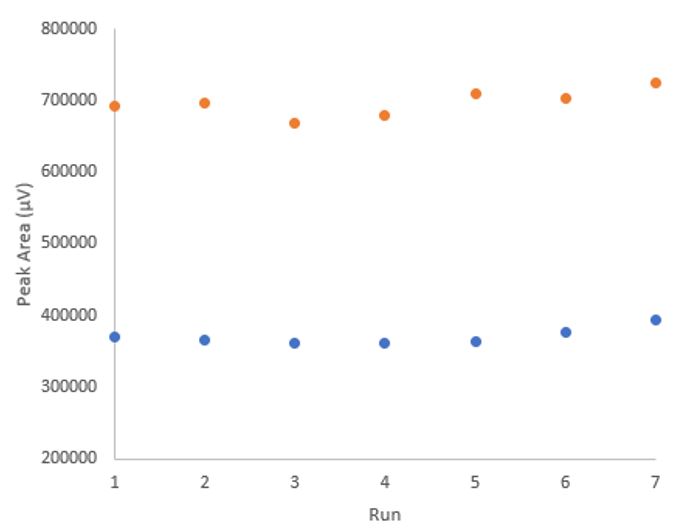

Repeatability was tested by analysing multiple samples from the same source. Table 3 shows the repeatability data whilst Figures 4 and 5 show graphic representation of the repeatability of the TOGA analyser.

Table 3. Repeatability values

Fig 4. Repeatability data N2 and CO2

Fig 5. Repeatability data CH4

The repeatability data shown above is well within the defined limits specified by ASTM D3612 (N2 <5%, CO2 <4%, CH4 <4%).

Conclusion

Full separation of all components of interest with easy and reliable quantification results in very good repeatability using the SCION Transformer Gas Oil Analyser. The analysis of dissolved gases in transformer oil according to ASTM D3612, method C, can also be performed perfectly with the SCION TOGA analyser with headspace sampler.

Download Application Note

Download the complete Application Note: Transformer Oil Gas Analysis via Headspace Sampling (ASTM D3612)

Gas Chromatography Solutions

A SCION Gas Chromatography Analyser was used to conduct this research. Providing excellent solutions for Environmental, Oil and Gas and Chemical industries, find out more about Scion GC Analysers.

If you would like to find out more, simply contact a member of our team. We look forward to hearing from you.

To be the first to hear about future research articles from SCION Instruments, be sure to join us on social media and sign up to our eNewsletter via the links below.