Trace Impurities in Mixed Xylenes by GC UOP Method 931-10

Introduction Method 931-10

This method is for determining trace impurities in high-purity mixed xylenes by gas chromatography (GC). Specific trace impurities determined include non-aromatic hydrocarbons, benzene, toluene and individual C9 and C10 aromatic compounds. C10 or higher non-aromatics, if present, may interfere with the determination of benzene. These can be determined by UOP Method 543. The lower limit of quantitation for any single component is 1 mg/kg (mass-ppm). Impurities at concentrations above 500 mg/kg should be determined by UOP Method 744.

The sample is injected into a gas chromatograph that is equipped with an autoinjector, SSL injector, fused silica capillary column internally coated with poly(ethylene glycol), and a flame ionization detector.

The concentrations of individual or group impurities are determined by the external standard (ESTD) method of quantitation, wherein peak areas of the sample components are compared to the peak areas of a calibration blend analyzed under identical conditions and injection volumes.

| Injector | Split/Spitless 230°C |

| Carrier gas | Hydrogen,

Constant flow, 2.3ml/min |

| Capillary Column | Scion-Wax MS, SC32437 |

| Oven program | Initial 50°C, hold 5 minutes

8°C/min to 100°C 2°C/min to 120°C 20°C/min to 230°C hold 5 minutes |

| Detector | FID, 250°C |

| Injection Volume | 0.5µL |

| Software | Scion Instruments Compass CDS |

Table 1. Analytical conditions

Figure 1. 436 GC Sample Holder

Experimental

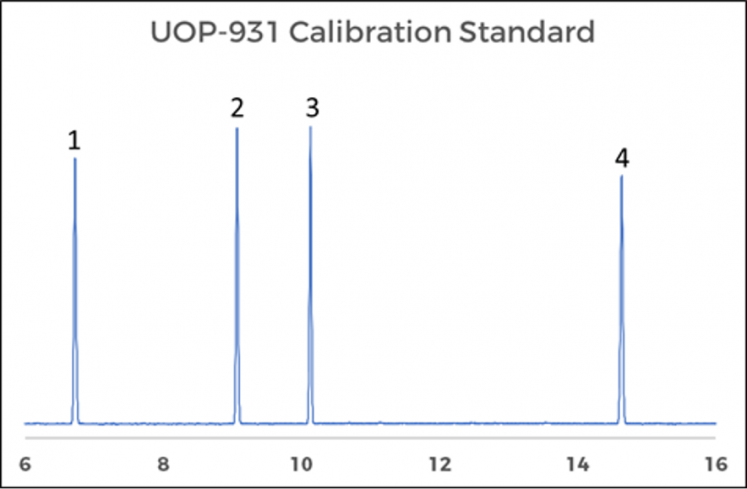

- Prepare a stock solution as described in ASTM Method D4307 to contain approximately 1.5 mass-% each of benzene, toluene, n-undecane and 1-methyl-2-ethylbenzene in n-heptane.

- Prepare the calibration blend to contain approximately 1.5 mass-% of the stock solution in heptane.

- Calculate the concentration of benzene, toluene, n-undecane and 1-methyl-2-ethylbenzene in the calibration blend to the nearest mg/kg

- Analyze the calibration blend in triplicate. The peak areas from each of the triplicate runs should not deviate from the average by more than 3%.

- Use the average peak areas to calculate the absolute response factor for benzene, toluene n-undecane and 1-methyl-2-ethylbenzene.

- Use the absolute response factor for n-undecane to calculate the concentration of the non-aromatics.

- Use the absolute response factor for 1-methyl-2-ethylbenzene to calculate the concentration of all C9, C10, and heavy aromatics

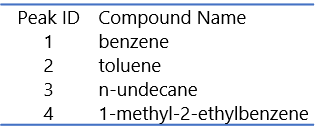

- Non-aromatics are determined as a composite group that includes all unidentified components eluting before ethylbenzene. The composite also includes benzene and toluene, if present. For some samples, benzene and/or toluene may be present and clearly separated from the nonaromatic components. In this case, benzene and/or toluene may be reported separately from the non-aromatics composite.

- Heavy aromatics are defined as a composite group that includes all unidentified components eluting after o-xylene.

Results

| Component | Concentration (mg/kg) | Response Factor |

| Benzene | 222.45 | 0.7590 |

| Toluene | 224.08 | 0.7583 |

| N-Undecane | 223.23 | 0.8198 |

| 1-Methyl-2-Ethylbenzene | 223.78 | 0.7727 |

Table 2. UOP 931 Calibration Blend

| # | Benzene | Toluene | N-Undecane | 1-Methyl-2-Ethylbenzene |

| 1 | 291.4 | 292.8 | 270.8 | 287.0 |

| 2 | 296.9 | 298.9 | 275.1 | 292.8 |

| 3 | 290.6 | 294.9 | 270.9 | 289.1 |

| N | 3 | 3 | 3 | 3 |

| Mean | 293.1 | 295.5 | 272.3 | 289.6 |

| Std Dev | 2.7 | 2.5 | 2.0 | 2.4 |

| RSD% | 0.92 | 0.85 | 0.74 | 0.82 |

Table 3. Repeatability Calibration Blend

| Mixed Xylenes 98+% | Mixed Xylenes 98% | P-Xylene 99% | M-Xylene 99% | O-Xylene 98% | |

| Area Non-Aromatics | 258.3 | 316.6 | 274.9 | 50.9 | 2015.0 |

| Area Xylenes | 1497366.2 | 1427908.0 | 1763566.0 | 1721710.2 | 1431071.1 |

| Area Aromatics | 124.5 | 1235.7 | 41.8 | 419.5 | 409.7 |

| Non-Aromatics (mg/kg) | 155.8 | 191.03 | 165.9 | 30.7 | 1215.81 |

| Aromatics (mg/kg) | 75.06 | 744.94 | 25.2 | 252.9 | 247.0 |

| % impurity in sample | 0.026 | 0.11 | 0.018 | 0.027 | 0.17 |

Table 4. Analysis of (mixed) xylenes samples

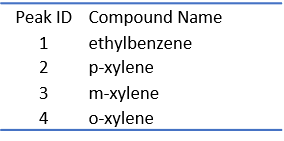

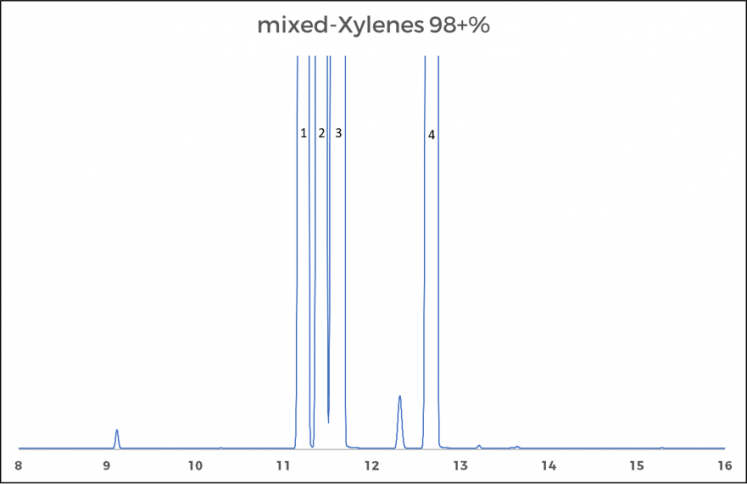

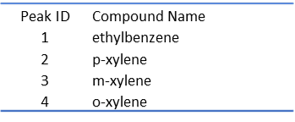

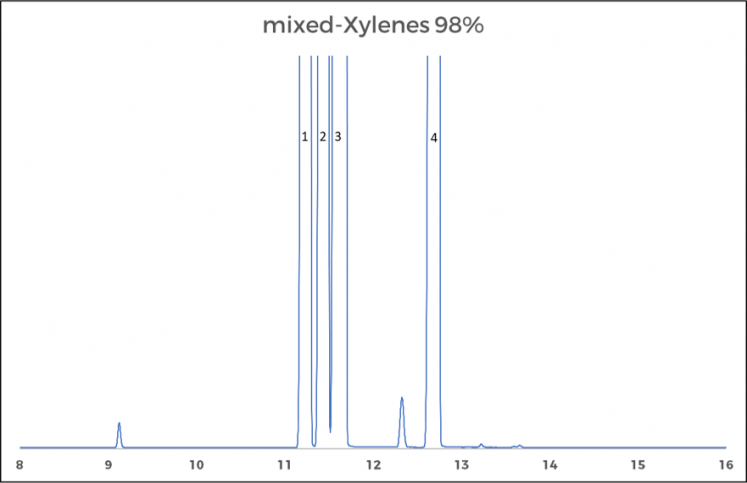

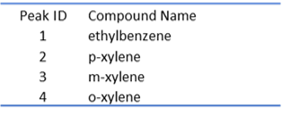

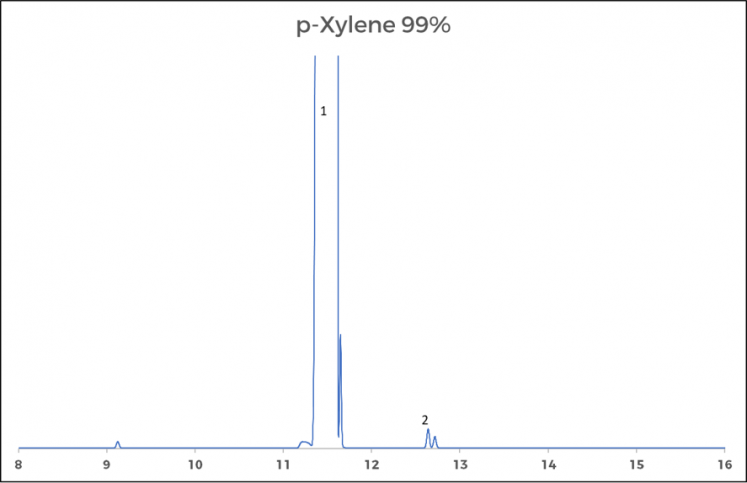

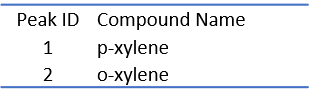

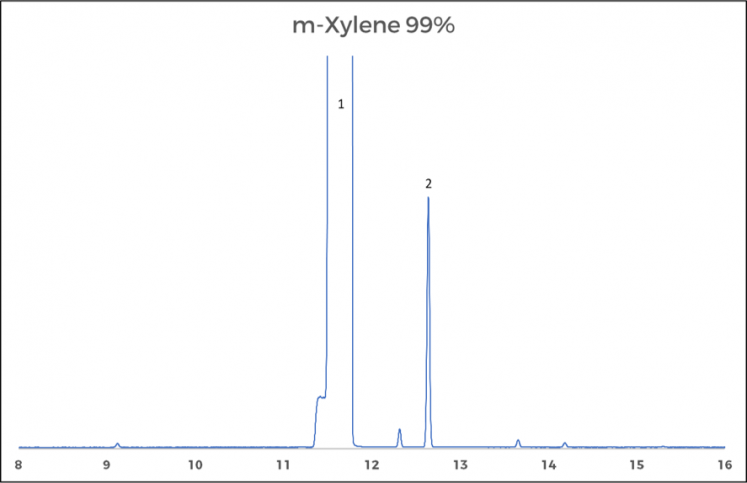

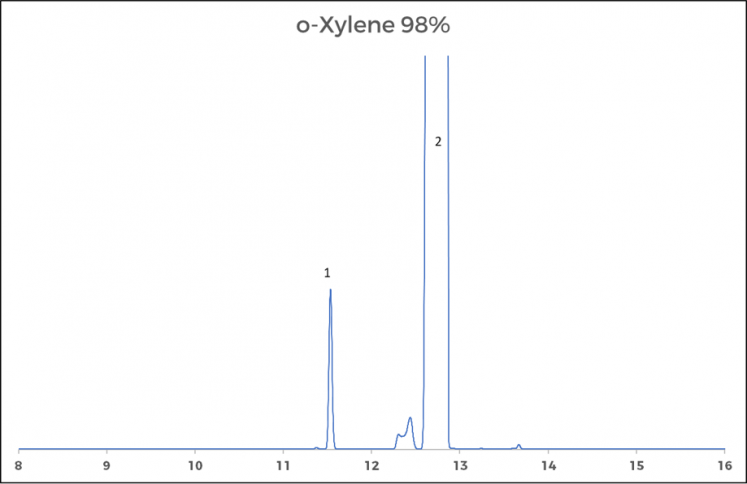

Chromatograms

Figure 2.

Figure 3.

Figure 4.

Figure 5.

Figure 6.

Figure 7.

Figure 8.

Conclusion

The obtained results demonstrate that this SCION Instruments configuration for the analysis of mixed xylenes according to UOP 931-10 operates within the criteria set forth in the referenced method.

Download Application Note

You can download the complete Application Note: Trace Impurities in Mixed Xylenes by GC UOP Method 931-10

SCION GC

In this application a SCION 436 GC was used to conduct this research. Find out more about the SCION 436 GC.

If you wish to speak to a member of our team about more information, please don’t hesitate to contact us. Or if you wish to keep up to date with SCION Instruments latest research and articles, why not join us on social media and sign up to our newsletters today?