The Determination of True Boiling Point data in Light hydrocarbon streams by Ultra-Fast DHA and Fugacity Film model Software modelling

Introduction

Distillation data is an intrinsic part of refining processes with data embedded in product specifications and regulatory compliance. In order to maximise product value, precise distillation data is vital. ASTM D86 (1) is the basic test method of determining the boiling point range of petroleum products and is one of the oldest methods still applicable within ASTM jurisdiction. ASTM D86 entails a rather basic controlled physical distillation, and it has some drawbacks in today use:

- It has a long cycle time, in most cases over 30 minutes, whereas many laboratories and processes require a faster delivery.

- The method requires 100ml of sample. In some cases the amount of sample available is too small to run the test. Moreover, sample size of 100ml may be regarded as environmentally unacceptable.

- A manual method requiring constant operator attention, has much lower productivity, and is less (cost) effective.

- A physical distillation of flammable samples in an open laboratory does come with an inherent safety risk that may be eliminated

Traditional DHA is way too slow as a method, and Simulated Distillation, despite being widely accepted, and sometimes even acceptable from regulatory point of view, does not provide the level of detail needed for the more volatile fractions and streams available. This application note details a new method, based on high speed DHA style chromatography and data modelling specifically geared towards TBP data for volatile streams. This Fugacity-Film model approach was first described some two decades ago, and it is based on Fick’s Law and Henry’s Law and has already been proven to allow for experimental prediction/modelling of TBP curves with relatively good precision.

Experimental

A system was set up based of a model 436-GC, with S/SL inlet and FID. The S/SL was EFC controlled in Constant Pressure mode, with a glass wool inert liner acting as solvent barrier for optimal injection profiles. A dedicated DHA to D86 column was used, delivering a minimum required separation for the software model to still be effective. CompassCDS was used as Chromatography Data Software, and StillPeaks DHA to D86 for modelling to D86.

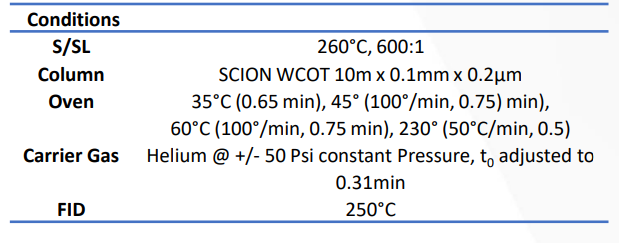

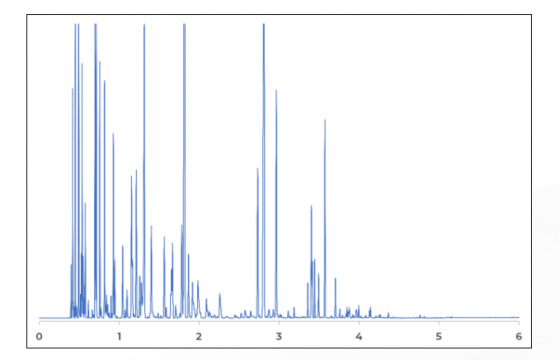

Method/Conditions for the instrumentation can be found in Table 1.

Table 1. Analytical instrumentation conditions

nC5-nC14 n-alkane mixtures were obtained for verifying retention times and identification. Live samples were obtained from various sources, covering the wider range of possible streams. All samples were injected neat using an 8400 autosampler, at 0.2 µl to avoid column overload and peak broadening on the relatively thin column film.

Results

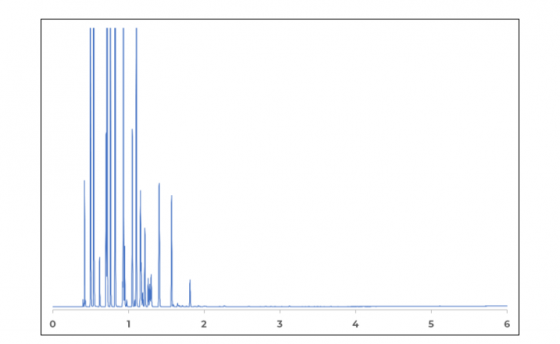

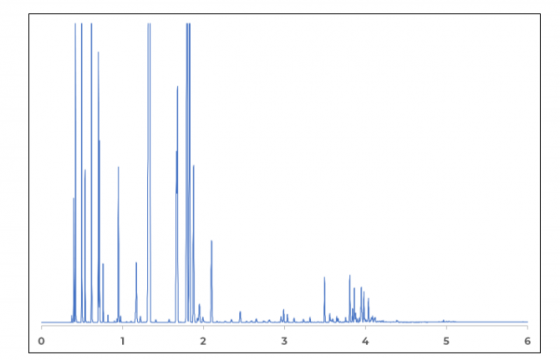

Figures 1 through 6 show typical Ultra-Fast DHA, chromatograms as obtained, with the derived TBP curves (selected samples).

As demonstrated, the time to result is a mere 6 minutes.

Figure 1. DHA to D86 chromatogram: Naphtha

Figure 2. DHA to D86 chromatogram: Alkylate

Figure 3. DHA to D86 chromatogram: Gasoline

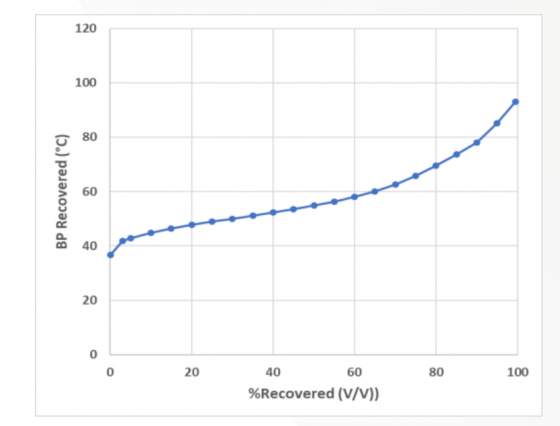

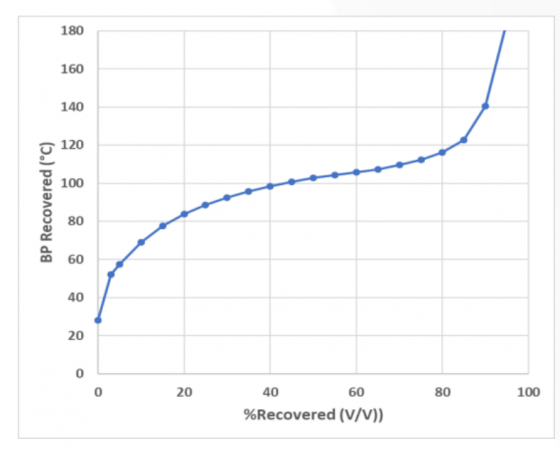

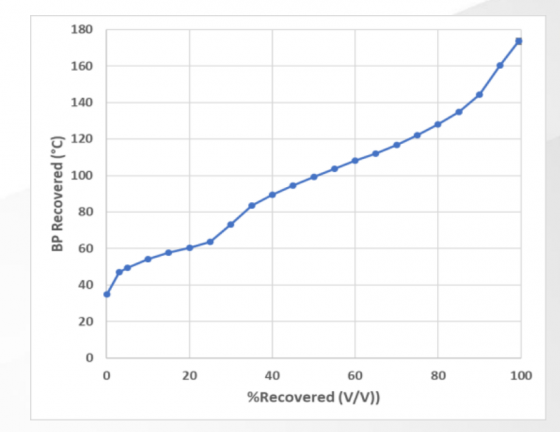

Figure 4. DHA to D86 Derived TBP: Naphtha

Figure 5. DHA to D86 derived TBP: Alkylate

Figure 6. DHA to D86 derived TBP: Gasoline

Results

Accuracy & Precision

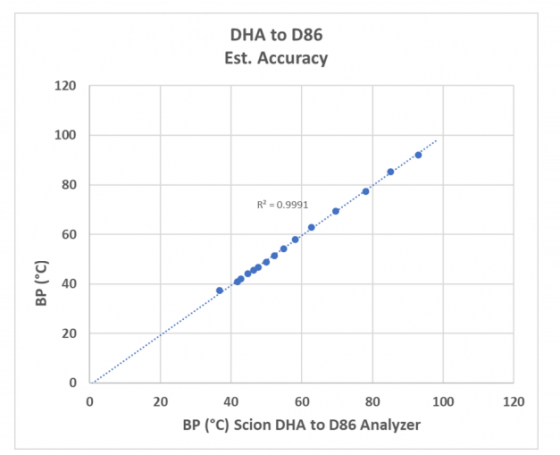

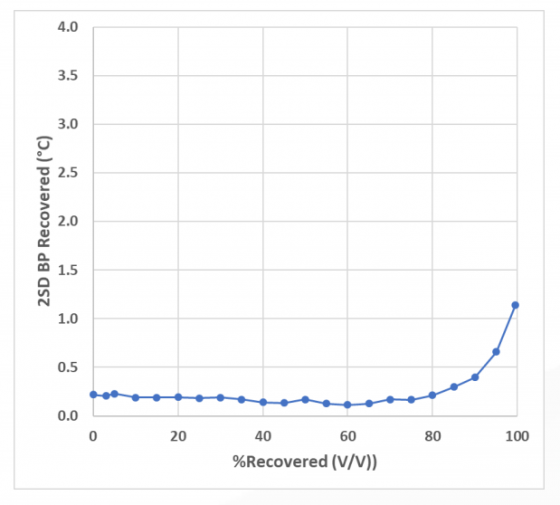

In order to demonstrate correlation between proposed solution and data provided from samples as provided, correlation plots were constructed. Figure 7 demonstrates the correlation plot for Naphtha over the samples BP range (n=10). To establish (partial) Precision, a repeatability test was run on several of the samples. Figure 8 shows repeatability in °C as calculated for the Naphtha sample (n=10),

Figure 7. Correlation Plot. Obtained TBP vs reference sample data as provided: Naphtha (n=10)

Figure 8. Repeatability (as 2sigma) for DHA to D86 for Naphtha (n=10)

Here, a correlation >0.999 was obtained, illustrating the striking similarity between data-sets (and methods) as used. Other samples also gave >0.999 correlation values across the board. Repeatability for the method is excellent. As shown in Fig 8, the typical 2sigma variance is <0.5°, and increase slightly to be approximately 1°C when approaching the Final Boiling Point. Even though this will require a more elaborate statistical evaluation to meet the required degrees of freedom, the solution seems to have better precision as compared to the precision as stated in the D86 method.

Conclusion

A promising new solution was proposed and tested as an alternative to D86, for analysing light hydrocarbon (blend) streams. The method, based on Ultrafast DHA and smart TBP modelling, provides significant benefits over D86 classical physical distillation, and may therefore be considered a valid alternative to it, in situations where this is allowed.

DHA to D86 delivers:

- D86 similar data

- Fast results (6 mins vs >30 in D86), short cycle times.

- Better precision (needs more data but this seems to confirm earlier findings).

- Method uses only 2ml of sample

- Automation, throughput increase up to factor 10.

- No/limited fire hazard (only 2ml sample, no distillation).

Download Application Note

Download the complete Application Note: True Boiling Point data in Light hydrocarbon streams by Ultra-Fast DHA and Fugacity Film model Software modelling

SCION 436 Gas Chromatographer

A SCION 436 GC was used to conduct this research. Providing excellent solutions for the simultaneous detection of six synthetic food dyes. Find out more about the SCION 436 GC.

If you would like to get in touch with a member of our team, please don’t hesitate to contact us. Or to stay up to date with future research and articles from SCION Instruments, sign up to our news letter via the button below or follow us on LinkedIn, Facebook and Twitter.