Optimization of volatile petroleum hydrocarbons analysis by automated headspace using method development tools.

INTRODUCTION

The Commonwealth of Massachusetts Department of Environmental Protection (MassDEP) developed a purge and trap method for analyzing water and soils for volatile petroleum hydrocarbons (VPH) in the early 1990s in response to numerous fuel oil spills and contaminated sites within the Commonwealth. The May 2004 Revision 1.1 method indicates that “There may be better, more accurate, and/or less conservative ways to produce VPH target and range data. MassDEP encourages methodological innovations”

In keeping with the spirit of “methodological innovations”, the current VPH method will be evaluated with the HT3 automated headspace vial sampler using the dynamic trapping capability that follows the trap recommendation of the method. The method recommends a trap of at least 25 cm long with an inside diameter of at least 0.105 inches. The method optimization mode (MOM) of the HT3 will be used to methodically determine optimum conditions for both waters and soils. The soils will be evaluated without methanol, following the recommendation cited in Section 1.12 (d) of the method to reduce the use of toxic solvents and generation of hazardous wastes.

Calibration curves and method detection limits (MDLs) will be established for the full VPH target list demonstrating the MOM feature as a tool for method development and optimization.

Figure 1. SCION HT3 Headspace Sampler together with the SCION Instruments 8300 GC platform in combination with to 8700 SQ-MS.

The purge and trap method developed by MassDEP (formerly MADEP) in the 1990’s detects VPH with a photo ionization detector (PID) in series with a flame ionization detector (FID). This method also lists numerous USEPA and other methods for the determination of gasoline range organics in water and soil matrix. These methods recommend the use of static headspace to pre-screen potentially high concentration samples to reduce system contamination. Additionally, MassDEP recently issued a draft copy of the VPH method in February 2012 to provide laboratories the ability to use mass spectrometry for VPH detection. As GC/MS has become more prevalent in environmental laboratories, other GC detectors have become less common, requiring the methods updates to allow for flexibility. The draft method also permits the percent relative standard deviation (%RSD) of the target VPH analytes or hydrocarbon range to be less than 25%.

This application note will outline the use of the SCION Instruments HT3 and MOM to develop a method for running VPH compounds by dynamic headspace. Because the HT3 is equipped with a dynamic trapping system (sweep) it is capable of detecting low ppb ranges of volatile contaminates in environmental samples, similar to ranges of purge and trap instrumentation. This study asserts the HT3 MOM will greatly enhance method optimization and expedite over-all method development. Additionally, the potential exists to simplify the MassDEP draft method by analyzing soil samples without the need for methanol extraction, methanol preservation, and potential liquid transfer effects.

MOM software will be utilized to optimize the dynamic trapping feature of the headspace instrument to meet the method requirement of the draft MassDEP VPH method.

INSTRUMENT CONDITIONS

The automated headspace analyzer, equipped with a Vocarb 3000 trap, was connected to a GC/MS. A Restek Rtx®-502.2 column was used with helium as the carrier gas. Table 1 displays the HT3 automated headspace vial sampler parameters and GC/MS parameters.

Table 1. Instrumentation operating conditions.

| Injector | Split 20:1, 200 °C |

|---|---|

| Column | Rtx-502.2 |

| Oven Program | 50°C (5 min), 11°C/min to 130°C, 20°C/min to 250°C (1 min) |

| Carrier | Helium |

| Flow | 0.9 ml/min |

| Software | MSWS/ HT3 Teklink |

| MS Transfer Line Temperature | 250°C |

| Ion Source | 250°C |

| Ionization Mode | EI |

| Scan Start | 2.5 |

| Scan Mode | Full scan |

| Water | Soil | |

|---|---|---|

| Oven temperature | 200°C | 200°C |

| Transfer line temperature | 200°C | 200°C |

| Sample temperature | 45°C | 45°C |

| Sample equilibrium | 5 min | 1 min |

STANDARD PREPARATION

A stock 100 ppm VPH standard was prepared in methanol from a 1000 µg/mL n-pentane standard and a 2000 µg/mL APH Volatile Standard. Eight working standards in the 1 ppb to 200 ppb range were prepared in water. 5 mL of each working standard were used for this study to mimic the purge and trap parameters. The soil samples were evaluated by adding 5 mL of reagent grade water to 5 g of soil.

A stock 50 ppm internal and surrogate standard (IS/SS) was prepared in methanol from a 2500 µg/mL EPA Method 8260B Internal and Surrogate standard. 5 µL of this 50 ppm solution was used to spike all samples.

STUDY PROCEDURE

The HT3 MOM allows users to set up an individual run with varying method parameters, as a tool for method development. The MOM software will be used to evaluate sample temperature, sweep flow rate, sweep flow time, and trap desorb time.

The HT3 utilizes a standard 0.125 in O.D. by 30.5 cm environmental trap. A Vocarb 3000 trap was used for this study.

5 mL of the standards were used for all evaluations. Soil samples consisted of 5 g of clean sand, to which 5 mL of the appropriate standard was added. This mimics a proposed change to the draft method in which water is added to soil samples in place of methanol, eliminating the need of methanol in the field. All samples and blanks had 5 µL of the 50 ppm internal standard/surrogate standard added for a final sample concentration of 50 ppb.

Water standard temperatures were adjusted from 25 °C to 55 °C in 10 °C steps, utilizing the MOM software, while soil samples were heated to one consistent platen temperature.

Two different studies were used to ascertain the effect of time and velocity on compound trapping efficiency (both producing the same volume of gas used to sweep the vial). The sweep time was increased from 2 to 8 minutes in 2 minute steps, while the sweep flow rate was maintained at 150 mL/min during this evaluation. The sweep flow rate was then examined from 50 to 200 mL/min in 50 mL/min steps, while the sweep flow time was held constant at 6 minutes for this evaluation.

Finally, the trap desorption time was evaluated from 0.5 minutes to 2.75 minutes in 0.75 minute increments to determine the effect on sample recovery and chromatography. These parameters were used to create an optimized dynamic headspace method. Water and soil sample curves from 1 ppb to 200 ppb were created without and with the base modifier, trisodium phosphate dodecahydrate for the target VPH analytes and the collective aliphatic/aromatic hydrocarbon ranges. Minimum detectable limits for the VPH compounds were also similarly determined with 7 samples prepared at the 1 ppb level.

SAMPLE TEMPERATURE RESULTS AND DISCUSSION

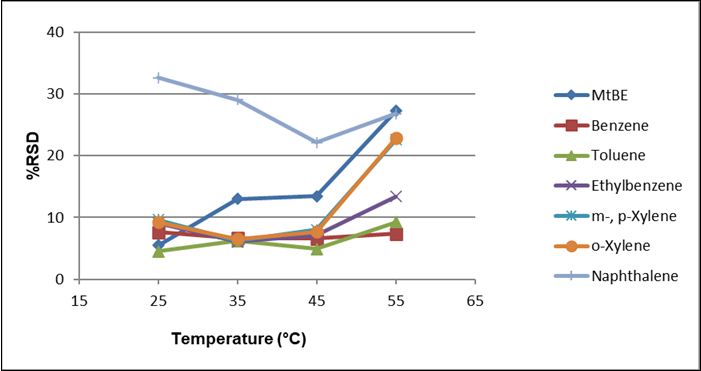

The data for all four platen temperatures were evaluated based on the calculated relative response factors (RRF) for the target VPH analytes and the collective aliphatic/aromatic hydrocarbon ranges following the method requirements. %RSD was determined for the compounds. The peak area data was also evaluated.

Figures 2 and 3 depict the %RSD graphs for the target and aliphatic/aromatic hydrocarbon ranges. The 45 °C platen temperature was chosen as the better temperature for all compounds. Naphthalene, m- and p-xylene and methyl t-butyl ether had the lowest %RSD and the highest peak areas at this temperature, while still maintaining reasonable peak areas for the other VPH compounds.

In order to evaluate other sweep parameters and minimize the effects of temperature, the same constant 45 °C platen temperature was used for soil samples.

Figure 2. %RSD of the Aliphatic and Aromatic Hydrocarbon Range Compounds with Varying Sample Temperature

Figure 3. % RSD of the Target Analytes with Varying Sample Temperatures

SLEEP FLOW TIME RESULTS AND DISCUSSION

The data for the four sweep flow times with a constant sweep flow rate of 150 mL/min for each matrix were evaluated based on the calculated RRFs for the target VPH analytes and the collective aliphatic/aromatic hydrocarbon ranges following the method requirements. The peak area data was also evaluated.

The water samples indicated reasonable data with a sweep flow time of 2 to 6 minutes. The soil samples indicated reasonable data from 4 to 8 minutes. Figure 4 shows the %RSD of the target analytes in water. The 6 minute sweep time was chosen, as it demonstrated the best average %RSDs for the compounds of interest.

Figure 4. %RSD for the Water Target Analytes with Varying Sweep Flow Times

SLEEP FLOW RATE RESULTS AND DISCUSSION

The data for the four sweep flow rates with a constant sweep flow time of 6 minutes were evaluated based on the calculated RRFs for the target VPH analytes and the collective aliphatic/aromatic hydrocarbon ranges following the method requirements. The peak area data was also evaluated.

Both water and soil samples indicated reasonable data for all flow rates. The 150 mL/min flow rate was chosen for the desorption analysis. Figure 5 is the %RSD of the target analytes in water.

Figure 5. %RSD for the Water Target Analytes with Varying Sweep Flow Rates

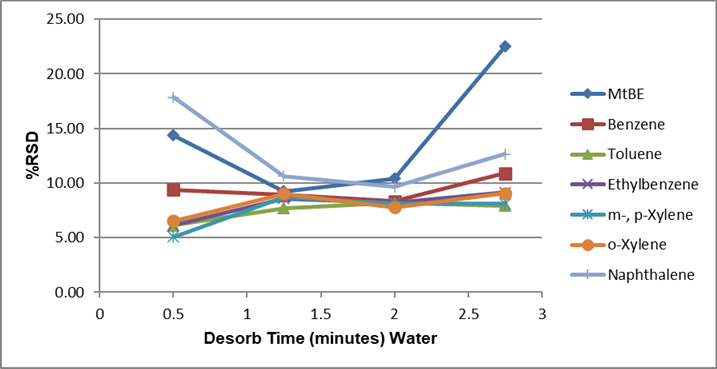

DESORB TIME RESULTS AND DISCUSSION

The data for the four trap desorption times were evaluated based on the calculated RRFs for the target VPH analytes and the collective aliphatic/aromatic hydrocarbon ranges following the method requirements. The peak area data was also evaluated.

Both water and soil sample indicated a desorb time between 1.25 and 2.0 minutes and provided reasonable data for all analytes. Figure 6 shows the %RSDs of the target analytes in water.

Figure 6. %RSD for the Water Target Analytes with Varying Desorption Times

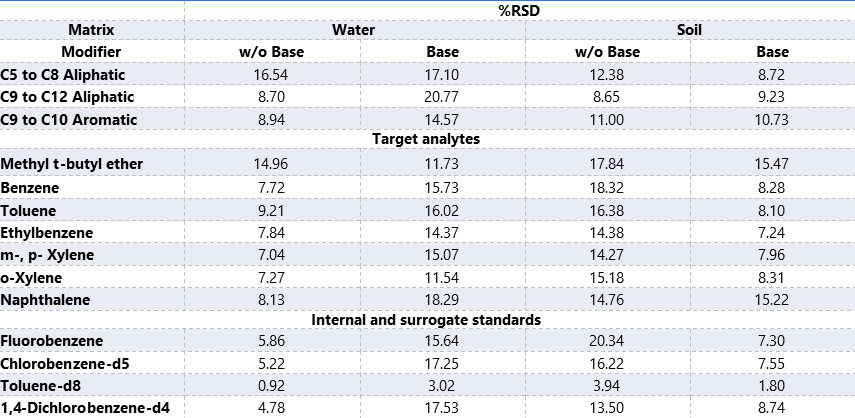

CALIBRATION CURVES AND MDL

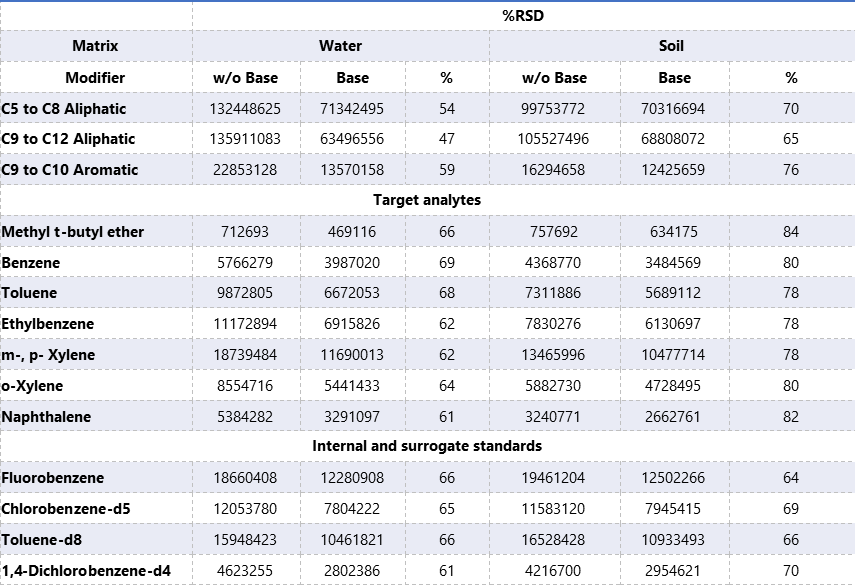

Once the various HT3 parameters were evaluated, optimal method parameters for this VPH analysis were chosen. These parameters are listed in Table 1. The samples were tested both without and with base modification Table 2 presents the calibration data for %RSD of this evaluation.

A significant difference was observed in the peak areas for all compounds between the base modified and non-base modified samples. The percent difference was calculated for the VPH analytes and the internal and surrogate standards. Table 3 presents this data.

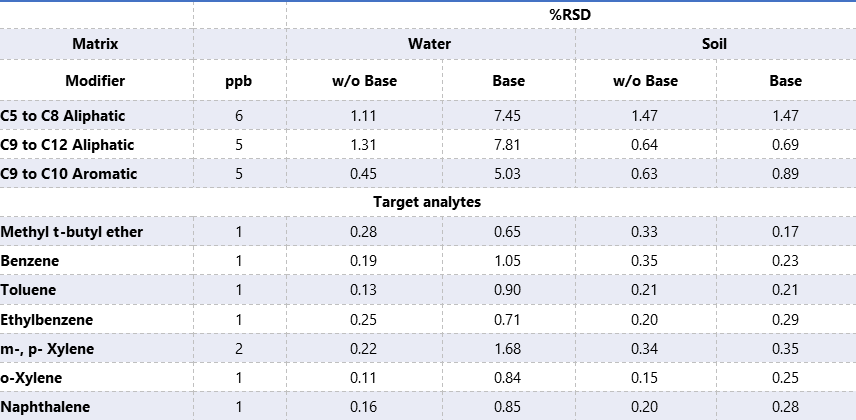

Method detection limits (MDLs) were determined by analyzing seven replicates at a 1 ppb concentration. These limits can be found in Table 4. Figure 7 shows a total ion current chromatogram (TIC) overlay of 50 ppb level standards for the water and soil.

Table 2. %RSD for Water and Soil Calibration Curves Without and With Base Modifier from 1 ppb to 200 ppb

Table 3. Peak Area of the 50ppm Standard of Water and Soil Without and With the Base Modifier and the Percent Difference (%)

Table 4. MDLs for Water and Soil Samples Without and With the Base Modifier

Figure 7. Overlay TIC Chromatograms of 50ppb Water (Blue) and Soil (Red) Calibration Standards

CONLUSIONS

The MOM feature of the HT3 automated headspace vial sampler facilitated the efficient determination of parameters related to the effects of sample temperature, sweep flow rate, sweep time and trap desorption times. Changes made to method parameters to optimize the dynamic headspace method would ultimately be advantageous to the MassDEP VPH draft method.

The optimized dynamic headspace method was used to determine the %RSD and the MDLs of VPH in water and soil samples from 1 ppb to 200 ppb. The %RSD values for all of the reportable compounds passed the MassDEP requirement of less than 25%.

MDLs were lower than the 1ppb standard for water and soil samples. MDLs were also lower for base modified soil samples. The MDLs were lower than the 1 ppb standard for the base modified water sample, except for the aliphatic and aromatic hydrocarbons and benzene. The base modifier had an effect on the peak area of all samples. The base modifier did not appear to have an appreciable effect on methyl t-butyl ether. Soil analysis by headspace also eliminates the need for methanol extraction and preservation required in the MassDEP method.

ORDER INFORMATION

| Part number | SCION HT3 Headspace |

|---|---|

| SC149300000 | HT3 Headspace Autosampler 110 V. This static headspace autosampler comes with our 60 position autosampler, 10 position platen heater, integrated Optimix equilibrium system, and completely heated Silcosteel sample pathway. Entire system can be heated from ambient up to 300C in increments of 1C. Valve and loop configuration includes 1ml standard loop. System's gas flows and pressure are electronically monitored and controlled. Windows XP or 2000 is required to operated the included HT3 TekLink software. Power requirements are 115V, 50/60 Hz, 10A. Make sure to order the appropriate GC interface cable to ensure proper installation. |

| SC149300100 | HT3 Headspace Autosampler 230 V. This static headspace autosampler comes with our 60 position autosampler, 10 position platen heater, integrated Optimix equilibrium system, and completely heated Silcosteel sample pathway. Entire system can be heated from ambient up to 300C in increments of 1C. Valve and loop configuration includes 1ml standard loop. System's gas flows and pressure are electronically monitored and controlled. Windows XP or 2000 is required to operated the included HT3 TekLink software. Power requirements are 230V, 50/60 Hz, 10A. Make sure to order the appropriate GC interface cable to ensure proper installation. |

| SC14930000S | HT3 Dynamic Headspace Autosampler 110V. This dynamic headspace autosampler comes with our 60 position autosampler, 10 position platen heater, integrated Optimix equilibrium system, and completely heated Silcosteel sample pathway. Entire system, including trap, can be heated from ambient up to 300C in increments of 1C. Valve and loop configuration includes 1ml standard loop. Dynamic mode includes 12" x 1/8" Tenax/Silica Gel and Charcoal (#3) trap and Vocarb 3000 (K) trap. Static and Dynamic modes may be used interchangeably throughout the same schedule. System's gas flows and pressure are electronically monitored and controlled. Windows XP or 2000 is required to operate the included HT3 TekLink software. Power requirements are 115V, 50/60 Hz, 10A. Make sure to order the appropriate GC interface cable to ensure proper installation. |

| SC14930010S | HT3 Dynamic Headspace Autosampler 230V. This dynamic headspace autosampler comes with our 60 position autosampler, 10 position platen heater, integrated Optimix equilibrium system, and completely heated Silcosteel sample pathway. Entire system, including trap, can be heated from ambient up to 300C in increments of 1C. Valve and loop configuration includes 1ml standard loop. Dynamic mode includes 12" x 1/8" Tenax/Silica Gel and Charcoal (#3) trap and Vocarb 3000 (K) trap. Static and Dynamic modes may be used interchangeably throughout the same schedule. System's gas flows and pressure are electronically monitored and controlled. Windows XP or 2000 is required to operate the included HT3 TekLink software. Power requirements are 230V, 50/60 Hz, 10A. Make sure to order the appropriate GC interface cable to ensure proper installation. |

Download Application Note

Download complete Application Note here: Optimization of volatile petroleum hydrocarbons analysis by automated headspace using method development tools

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, follow us on social media and sign up to our newsletter below.