IP507 Determination of boiling range distribution of heavy distillate and residual fuel oils — Gas chromatography method

Introduction

SCION Instruments offers the solution for a simulated distillation of heavy distillate and residual fuel oils.

Standardized method IP507 describes the determination of the boiling range distribution of heavy distillate and residual fuel oils, with initial boiling points (IBP) of at least 100°C and final boiling points of (FBP) above 750°C. This method is not applicable for analyzing bitumous samples or petroleum products containing low molecular weight components, such as naphtha’s, reformates, gasolines and diesels. Hetero atoms, such as alcohols, ethers, acids or esters or residue are not the be analyzed by this method.

Simulated Gas chromatography distillations can be used to replace conventional distillation methods for control of refining operations. Simulated distillations are a safer and faster way to perform an similar boiling range distribution of heavy distillates and residual fuel oils.

This application is applicable on the SCION Instruments 8X00 GC-platform, shown in figure 1.

Figure 1. SCION Instruments 8X00 GC platform equipped with the 8400PRO autosampler.

Results and Discussion

The SCION SIMDIST analyzer used for this application, comprises of a small footprint 8X00-GC, configured with a temperature programmable air cold on column (COC) injector with air cooling, a SCION SIMDIST column and a Flame Ionization Detector (FID) with ceramic HT flame tip.

A 8400PRO Autosampler was used in Standard On-Column mode. Standards were prepared in CS2 and used to determine system performance and response factors. A qualitative mixture of normal paraffins covering the range from C5 up to C120 was used to determine the relationship of boiling point (BP) versus retention times (RT). CS2 blanks were run and evaluated for cleanliness of the blank, for blank subtraction.

After running a calibration standard sample, the septum purge time is switched open after elution of the C120 peak, for cleaning the system for the next injection. This action is shown in figure 2, 4 and 6 at 40,5 minutes.

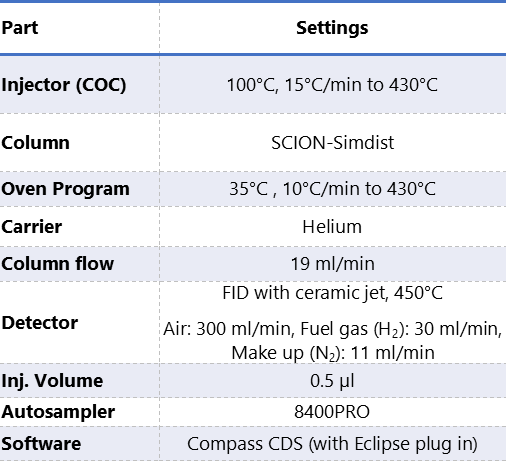

Table 1. Analytical conditions

Reference oil 5010 1%

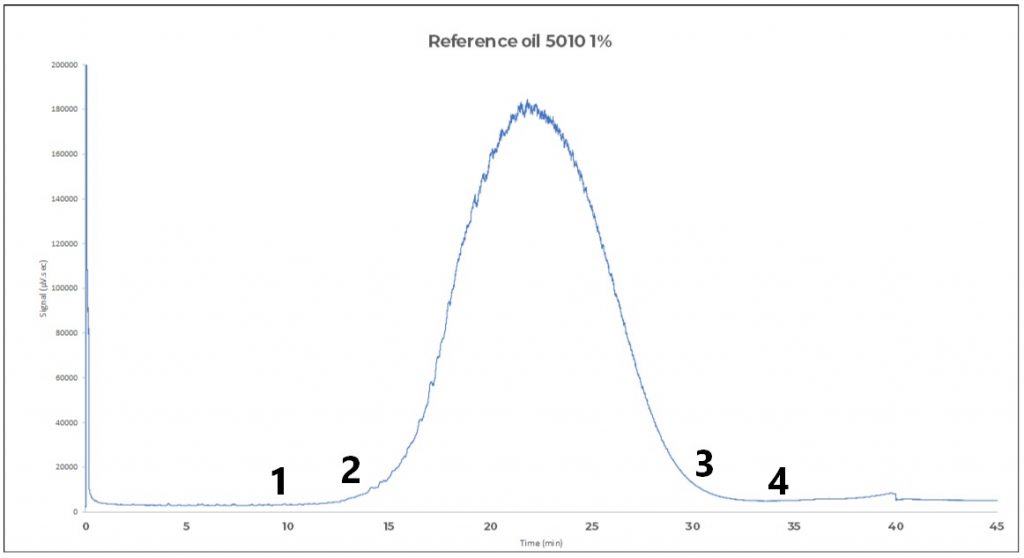

A reference oil with known initial boiling point and final boiling point is injected to check if the method and system are working correctly. See figure 2 and table 2 for the results and specifications of the reference oil. In figure 2, point 1 is the start of elution time, point 2 the initial boiling point (IBP), point 3 final boiling point (FBP) and point 4 is the end of elution of the sample.

Figure 2. Chromatogram Reference Oil 5010

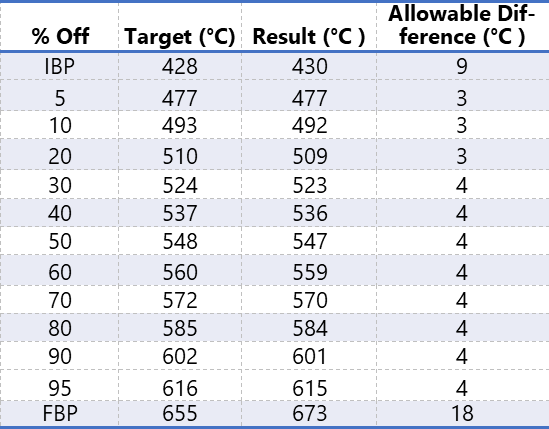

The results in table 2 show that all the critical points are within allowance.

Table 2. Results Reference oil 5010 1%

Repeatability of the reference oil is determined by analyzing 5 times the same sample consecutively. RSD(%) of the 5 measurements is 1.36%, which is excellent for simulated distillations.

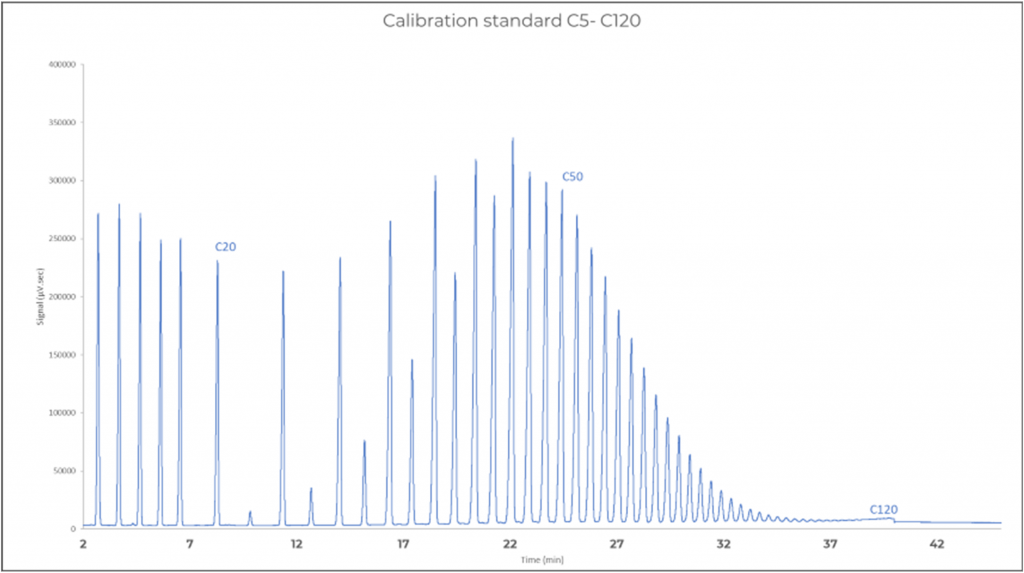

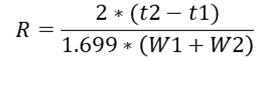

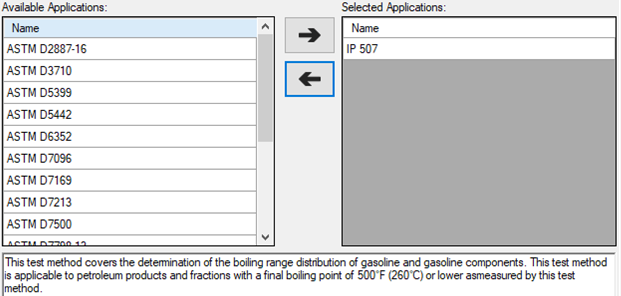

Calibration standard C5-C120.

A calibration sample is injected for identification of the n-alkanes during analysis of an unknown sample.

See figure 4 for the chromatogram of the calibration standard and figure 3 for the retention time vs. boiling point of the calibration standard.

Figure 4. Chromatogram Calibration mix

System performance

The resolution of the column can be determined by using the C50 and C52, peaks and following equation:

Where:

t1 = retention time in seconds for C50 peak

t2 = retention time in seconds for C52 peak

W1= width in seconds at half-height of C50 peak

W2= width in seconds at half-height of C52 peak

The calculated resolution is 2.57, which is excellent since a good column resolution is between 2 and 4.

Another critical point is the peak skewness of peak C20 at 5% peak height. A good peak skewness ratio shall not be less than 1 or greater than 3. The skewness of the C20 peak is with 1.04 within specification.

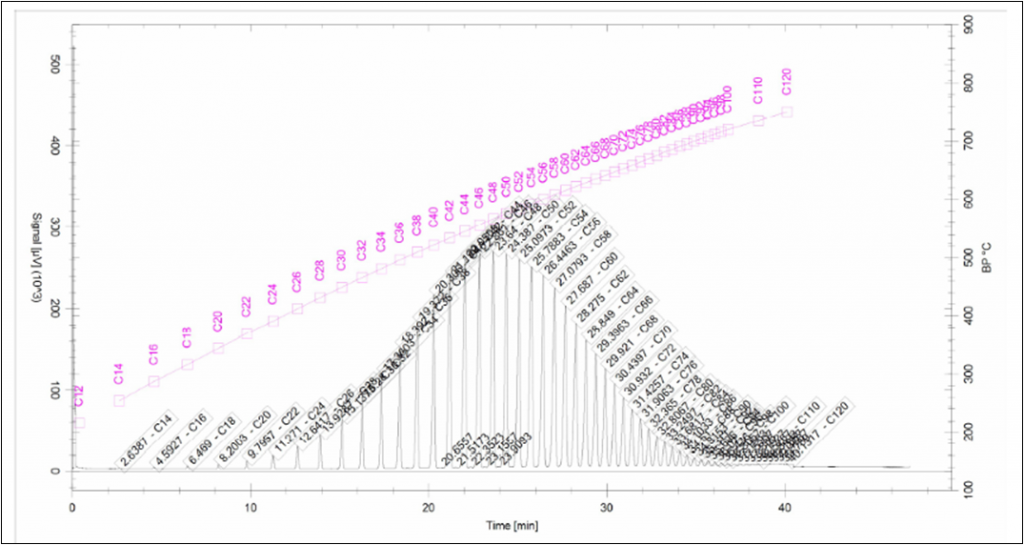

Figure 5 is showing a chromatogram using the Compass Eclipse software plug in, with combined Retention time vs boiling point curve.

Figure 5. Chromatogram calibration mix using the compass Eclipse software plug in and optional methods

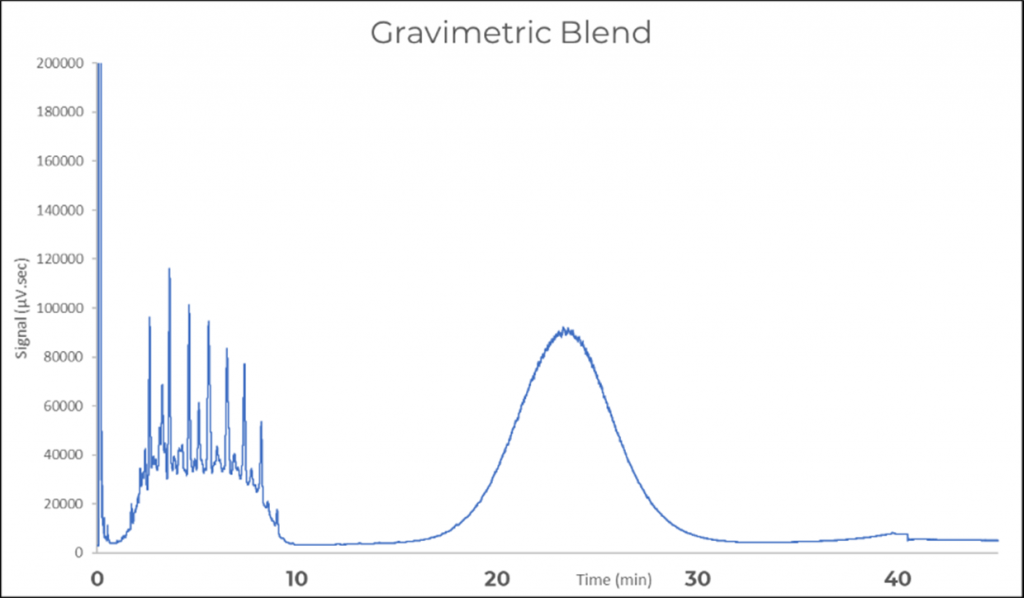

Gravimetric blend

A gravimetric blend is used for checking the relative response of the two distillates and to check the baselines at start, middle and end of the chromatogram. Figure 6 shows the chromatogram of analysis of the gravimetric blend, where a baseline separation is shown between the two peaks.

Figure 6. Chromatogram Gravimetric Blend

Calibration standards, of each target analyte, were prepared at a range of 0.2mg/L to 20mg/L in acetonitrile.

The analytical conditions of the analysis can be found in Table 1.

Conclusion

The SCION Instruments 8X00 GC-platform provides a robust and complete solution for the simulated distillation of heavy distillates and residual fuel oils, following standardized method IP507. The obtained results demonstrate that this method and SCION Instruments system configuration is excellent and meets all the required limits for IP507.

The equipment of the 8X00-GC analyzer is pre determined, for ordering information or customisation please contact your local sales representative.

Although the 4X6-GC series is not shown in this application note, it is possible to perform this analysis on the SCION instruments 4X6 GC series.

Download Application Note

Download complete Application Note here: IP507 Determination of boiling range distribution of heavy distillate and residual fuel oils — Gas chromatography method.

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, why not join us on social media and sign up to our newsletters today?