ASTM D2887-B - Fast Analysis of Boiling Point Distributions in Petroleum Fractions Using Simulated Distillation

Introduction

In many regions ASTM D2887 may be used for determining the boiling point distribution of petroleum products, feedstocks and fractions that have a final boiling point of 538°C or lower. This provides insight into composition and allows for the determination of intrinsic product value.

While Physical Distillation is still considered the reference method for distillation, and therefore mandatory in many countries for qualifying fuels, Simulated Distillation (SIMDIST) by gas chromatography offers some significant advantages over the physical procedure, making this technique quite useful.

Analysis by GC typically has the better precision, higher throughput, less hands-on time and lower cost per sample. Also, SIMDIST requires considerably less sample to be run and can generally be considered the safer of the two techniques.

In addition to the standard analytical method (procedure A), a second procedure is described in ASTM D2887 (procedure B), which is the accelerated (or fast) method, which is the subject of this application note.

This application note demonstrates a solution for D 2887 procedure B for analyzing Petroleum products covering a boiling point range from 36°C to 545°C.This procedure is also suited for biodiesels.

For gasolines, method D 7096 should be used.

- Boiling range distributions obtained by this test method are essentially equivalent to those obtained by true boiling point (TBP) distillation (see method ASTM D2892).

- The results are not equivalent to results from low efficiency distillations such as those obtained with methods ASTM D86 or D1160.

Experimental

The SCION SIMDIST analyzer comprises of either a 456-GC or a 436-GC, configured with a cool on column (COC) injector, a 5m x 0,53mm x 2.65µm SIMDIST column, and a Flame Ionization Detector (FID).

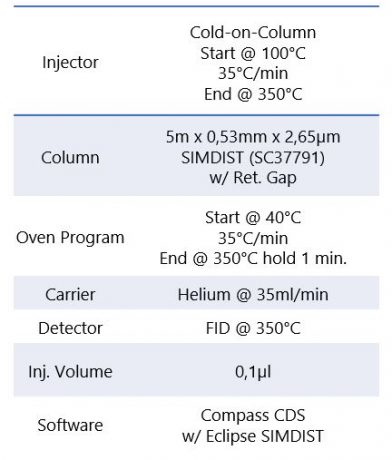

Analytical conditions for the SIMDIST analysis can be found in table 1.

A qualitative mixture of normal paraffins covering the range from C5 up to C44 (1% wt. each in CS2) was used to determine the relationship of boiling point (BP) versus retention times (RT).

Table 1. Analytical conditions

Results

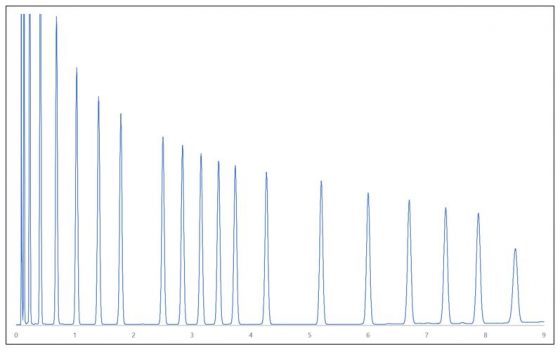

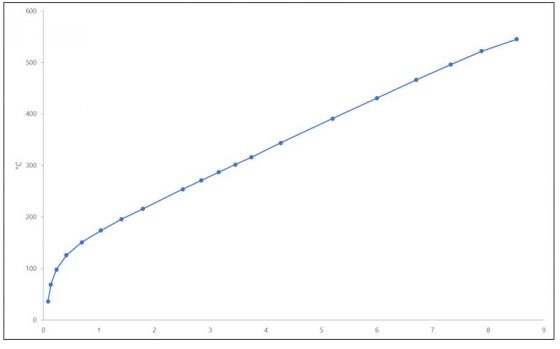

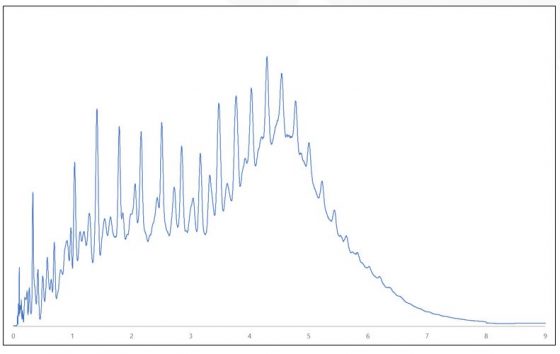

Figures 1 and 2 show a chromatogram of the normal paraffins calibration standard and the resulting RT vs BP calibration curve as used for this analysis.

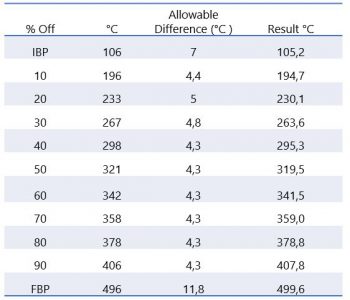

In order to check that the requirements of ASTM D2887 are met using this configuration, Reference Gasoil No. 2 was analysed 11 times, consecutively.

Figure 3 shows a chromatogram of this Reference Gasoil, with table 2 showing the analytical results set out against the reference values and maximum allowable deviations.

All results obtained via this method, using this configuration fall within the allowed limits for ASTM D2887.

Table 2. Results, reference values and allowable difference

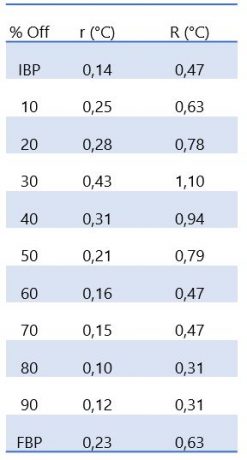

Table 3. Obtained Precision

Figure 1. D2887 Cal. STD (C5-C44)

Figure 2. D2887 Cal. STD (C5-C44)

Figure 3. Reference Gasoil No. 2

Conclusion

The obtained results demonstrate that this Scion Instruments SIMDIST configuration for ASTM D2887 procedure B passes the criteria set forth in the referenced method, with an analysis time that is 4x faster than procedure A.

Please note that:

- The gas chromatographic simulation of this determination can be used to replace conventional distillation methods for control of refining operations.

Download Application Note

Download the complete Application Note: Fast analysis of Boiling Point Distributions in Petroleum Fractions using Simulated Distillation (ASTM D2887-B)