ASTM D7900 Standard Test Method for Determination of Light Hydrocarbons in Stabilized Crude Oils by Gas Chromatography

Introduction

SCION Instruments offers the solution for detailed hydrocarbon analysis (DHA) of stabilized crudes. A stabilized crude oil is known for having a Reid Vapor pressure equivalent or less than 82.7 kPa. Crude oils consist of hundreds of hydrocarbon compounds in which the boiling point distribution of these crude oils is an important parameter in the petroleum industry.

ASTM D7900 describes the standard test method to determine the boiling point range distribution of hydrocarbons in crude oil up to n-nonane (n-C9). It is possible to combine the results of this method with the test results of ASTM D7169 and IP 545 to give a full boiling point distribution.

This application is applicable on the SCION Instruments 4X6 and the new 8X00 GC-platform, Figure 1 shows the new SCION Instruments 8X00 GC platform.

Figure 1. SCION Instruments 8300 and 8500 GC platform equipped with the 8400PRO autosampler.

Results and Discussion

The DHA ASTM D7900 is a perfect method for the determination of light hydrocarbons in stabilized crudes oil by gas chromatography.

This method determines the boiling point range distribution of hydrocarbons in stabilized crude oil up to n-nonane (n-C9). Identification is done using reference chromatograms and a database of hydrocarbon compounds.

Other test methods like ASTM D7169 or IP 545 also claim to give such boiling point distribution in crude oil. Unfortunately, the lighter part (up to n-C9) of the distribution and the total mass recovery of these methods are liable to significant errors. The ASTM D7900 was specially developed to determine the boiling point distribution of the front end more accurately without interference imposed by the diluent solvent (carbon disulphide).

However, it is possible to achieve a full boiling point distribution of the lower and heavier hydrocarbons by merging ASTM D7900 with ASTM D7169 or IP545.

The primary identification tool of this application is done with Kovats index. Using this index makes it easier to compare data between multiple systems. This method converts retention time to system independent numbers.

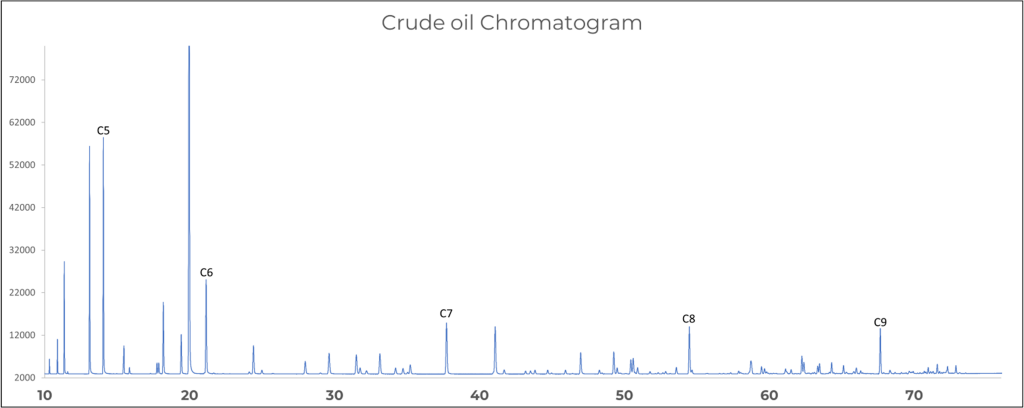

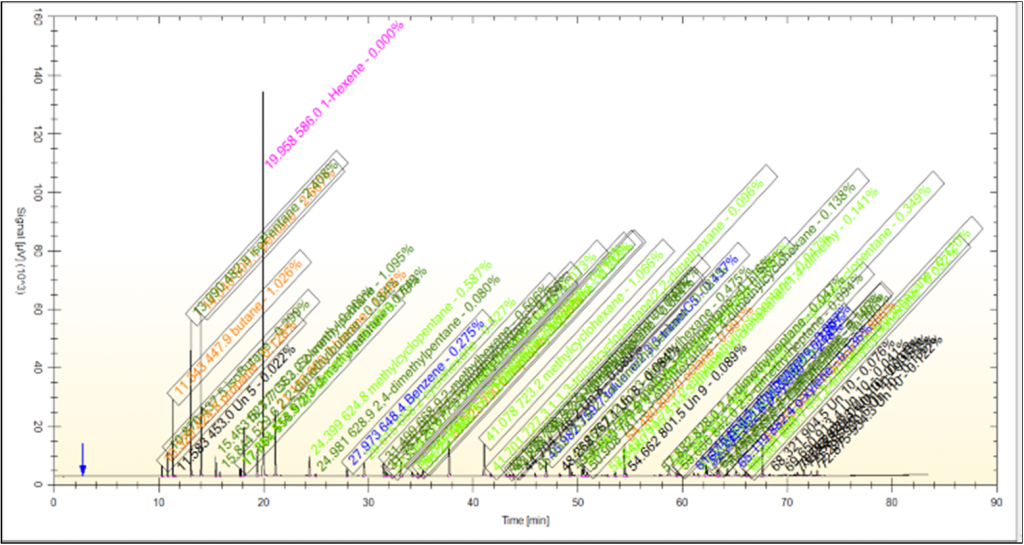

Figure 2: Example chromatogram of crude oil with 1-hexene as internal standard.

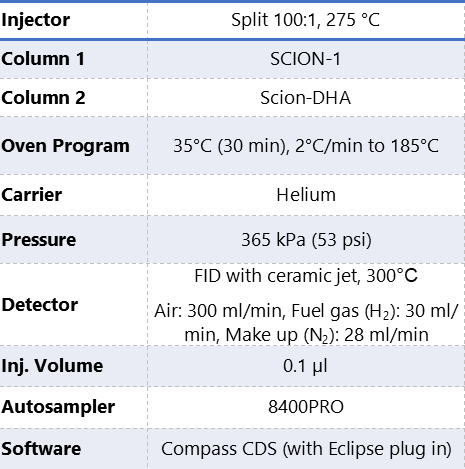

Table 1. Analytical conditions

Another advantage of this index is that there are only two psychical properties that determine this factor, solubility and the n-alkanes. While in comparison, retention times are dependent on six physical properties.

Ii = Kovats retention index peak i.

n = Carbon number n-alkane peak heading i.

N= Carbon number n-alkane peak after i.

ti = Retention time i.

to = air peak, void time.

To determine the Kovats index a calibration mixture of n-paraffins was injected in the system.

The indeces found are compared with known data in the database and the rest of the peaks are assigned accordingly. Based on this standard, the composition of the crude oil front-end can be identified and the boiling point distribution can be calculated.

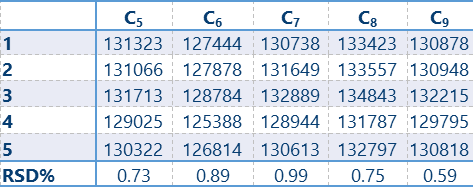

The repeatability of five components was tested by injecting a mixture of n-paraffins. The specification set in the ASTM D7900 states that the standard deviation should not exceed 0.1%. Table 2 shows an example of a Scion DHA D7900 analyser with excellent repeatability given as a percentage.

Table 2. Repeatability of 5 consecutive injections.

Figure 2 shows an example chromatogram of a crude oil sample. In the chromatogram a select group of compounds are named but with Eclipse software all components are successfully identified.

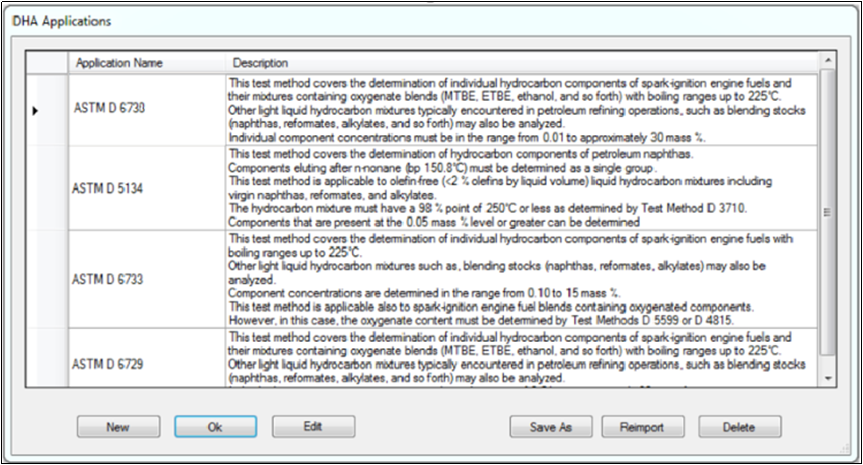

The CompassCDS Eclipse plug in is used for analysing the data. This is an addition to the basic Compass CDS and this will provide all the tools to calculate the necessary data.

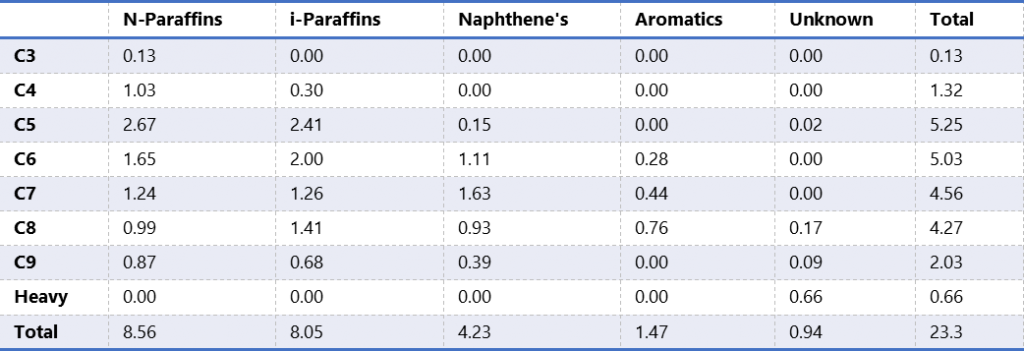

Table 3. Group report in mass% of the crude oil.

Table 3 shows the group report of the crude oil in mass (%). Based on the mass report and internal standard, a boiling point distribution was made. Table 4 shows this boiling point distribution.

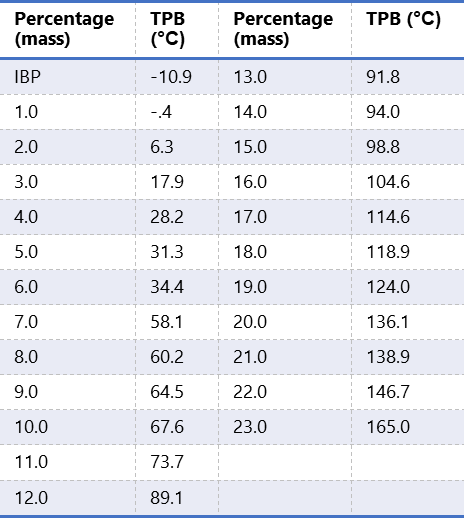

Table 4. Boiling point distribution report of the crude shown in figure 2

The data from table 4 can be merged with ASTM D7169 or IP545 for the total boiling point distribution of the crude oil.

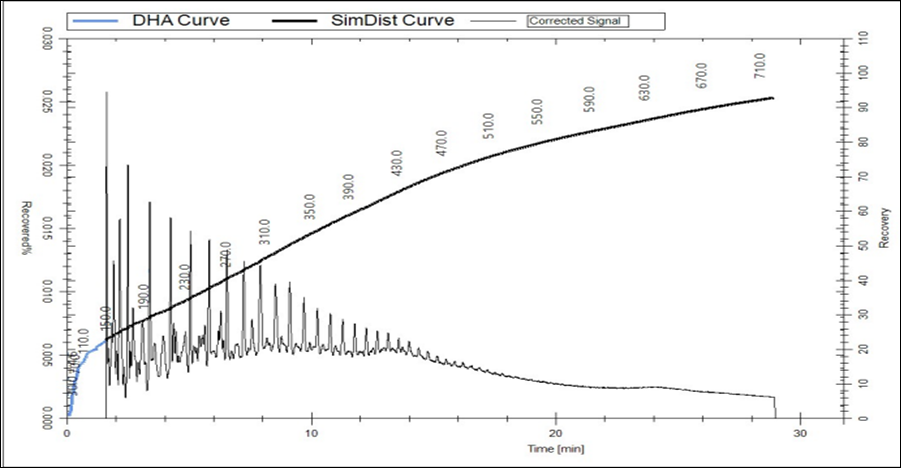

Figure 3 shows an example of the merged crude oils distribution report in Eclipse. The boiling point distribution until 151 °C is based on the DHA ASTM7900 data and is shown in blue. The simdist curve from 151 °C is based on ASTM D7169 and is shown in black.

Figure 3: Example of a merged crude oil distribution report in Eclipse.

SCION application note AN088 will give further information of the combination of ASTM D7169 and ASTM D7900 to give this full boiling point distribution Figure 4 shows an example of how the chromatogram will look like and as shown it is also possible to select other ASTM methods.

Figure 4: Chromatogram of a crude oil sample using the Compass Eclipse plug in.

Conclusion

The SCION 8X00-GC analyser is perfectly capable of analysing the boiling point distribution of the crude oil front end in compliance with ASTM D7900.

If a full boiling point distribution is necessary it is possible to combine this method with ASTM D7169 or IP545. For more information see SCION Instruments application note AN088 Crude Oil Analysis: Combining ASTM D7169 and ASTM D7900 to give a full boiling point distribution of crude oils.

The equipment of the 8X00-GC analyser is pre determined ordering information can be found on the next page, for customisation please contact your local sales representative.

Although the 4X6-GC series is not shown in this application note, it is possible to perform this analysis on the SCION Instruments 4X6 GC series.

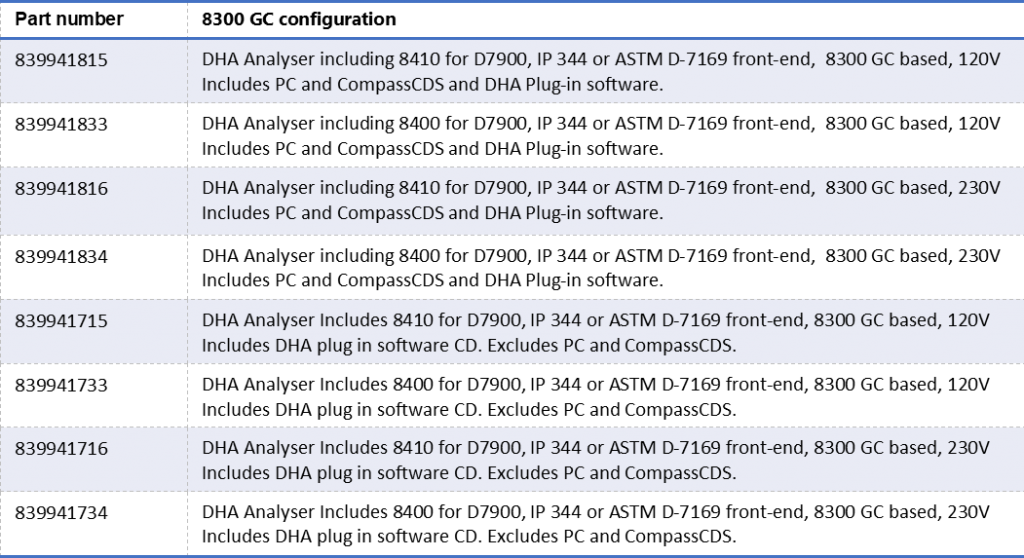

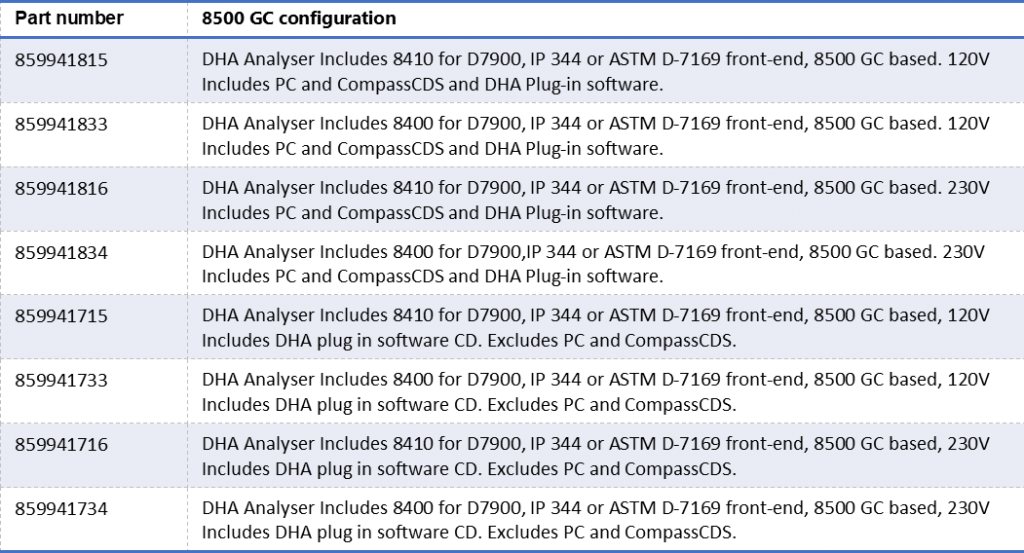

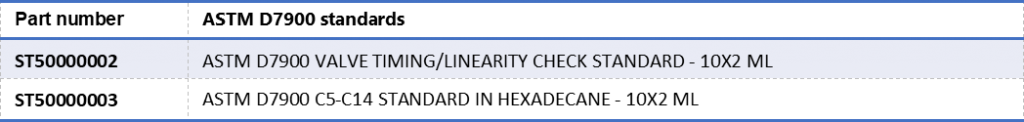

Order information

Download Application Note

Download complete Application Note here: ASTM D7900 Standard Test Method for Determination of Light Hydrocarbons in Stabilized Crude Oils by Gas Chromatography.

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, why not join us on social media and sign up to our newsletters today?