ASTM D7504 Standard Test Method for Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography and Effective Carbon Number.

Introduction

SCION Instruments offers the solution for trace impurities in monocyclic aromatic hydrocarbons by gas chromatography and effective carbon number.

After manufacturing products might contain impurities. The ASTM D7504 describes the determination of total nonaromatic hydrocarbons and monocyclic aromatic hydrocarbons in benzene, toluene, ethylbenzene, p-xylene, o-xylene, m-xylene and styrene. This method also calculates the purity of these components.

This application is applicable on the SCION Instruments 4X6 and the new 8X00 GC-platform, Figure 1 shows the new SCION Instruments 8X00 GC platform.

Figure 1. SCION Instruments 8300 and 8500 GC platform equipped with the 8400PRO autosampler.

Results and Discussion

The ASTM D7504 is a method for the determination of the purity, and total nonaromatic hydrocarbons and monocyclic aromatic hydrocarbons in benzene, toluene, ethylbenzene, p-xylene, o-xylene, m-xylene and styrene.

After manufacturing the product might contain trace impurities, this analysis can determine the type and amount of these hydrocarbon impurities. The limit of detection (LOD) of this method is 0.0002 mass % and limit of quantitation is 0.0006 mass % for impurities in toluene, m-xylene, p-xylene, o-xylene, ethylbenzene, benzene and styrene. This test method is suitable for setting impurity specifications and for the use of an internal quality control.

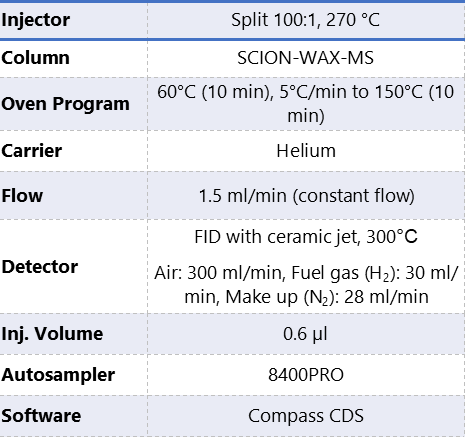

Table 1. Analytical conditions.

Typical impurities that can be found in the products are: alkanes (1 to 10 carbon atoms), benzene, toluene, ethylbenzenes, xylenes and aromatic hydrocarbons (>9 carbon atoms).

When looking at interferences it shows that the complete separation of p-Xylene, ethylbenzene and m-Xylene can be problematic when ethylbenzene or p-Xylene is analysed. According to ASTM D7504 the separation can be considered adequate when the distance from the baseline to the valley between two peaks is not greater than 50% of the peak height, this is determined by the lowest of the two peaks.

It is important to check the separations of these components with a check sample before implementing the method.

In addition, the check sample can be used to determine the retentions times of the components.

This method uses the effective carbon number (ECN) correction factors to adjust the peak area of each component. From this the concentration of the components are calculated based on its relative percentages of total adjusted peak area and normalized to 100.0000%.

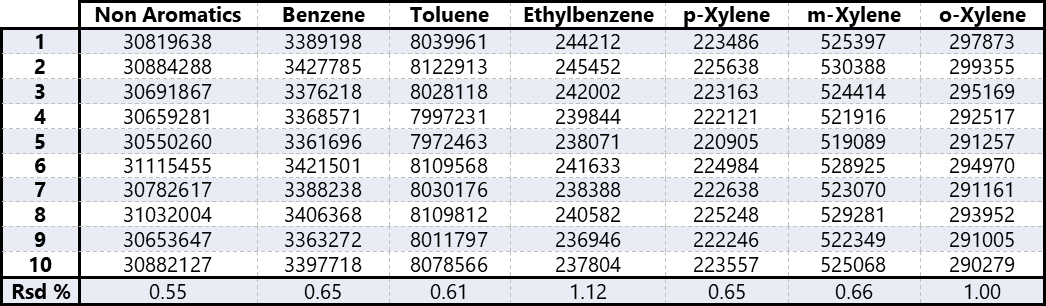

The repeatability of seven components was tested by injecting a custom made mix in tenfold. The results in table 2 show an excellent repeatability which meets the requirements set by ASTM D7504.

Table 2. Repeatability of ten consecutive injections using a custom made mix

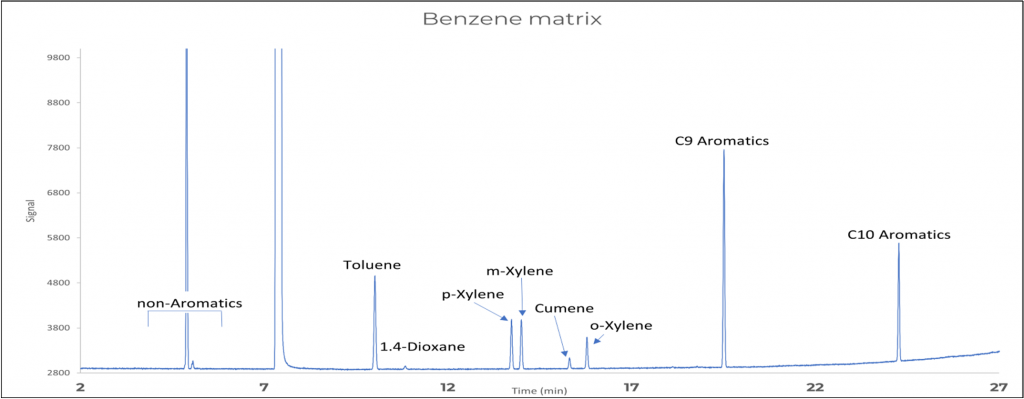

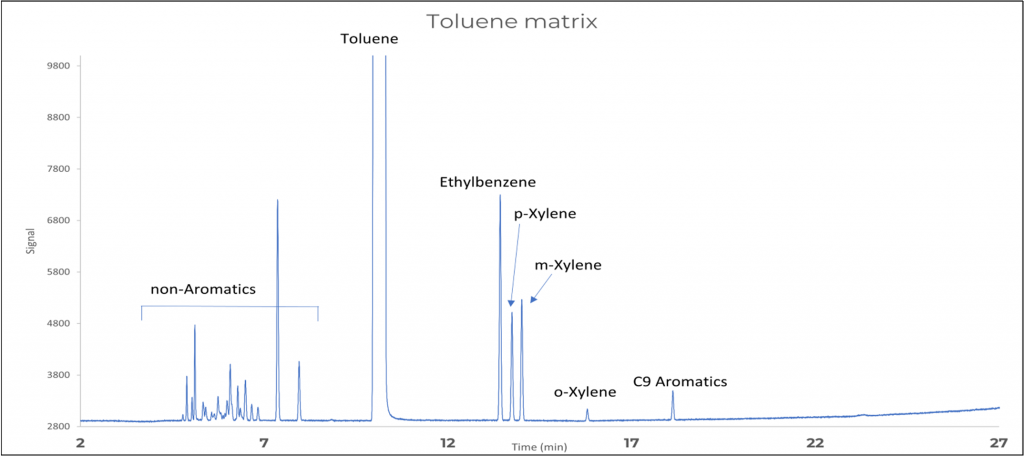

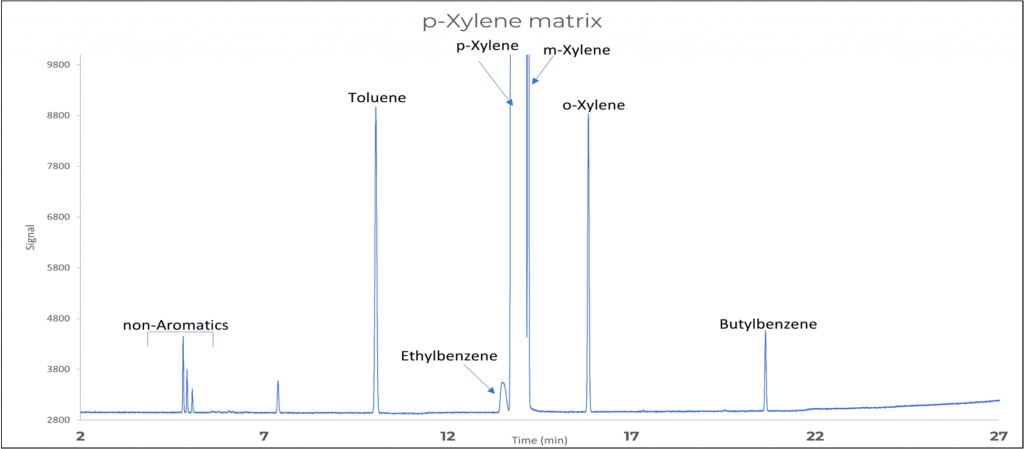

Figure 2 shows an example of three different samples in different matrixes, this also shows the separation between the critical components.

Figure 2. Example chromatograms of different sample matrixes.

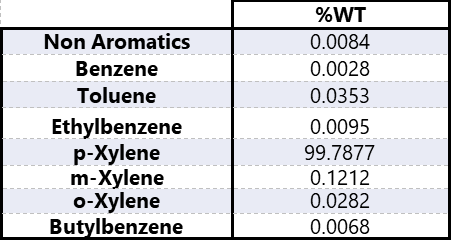

From the p-Xylene sample the %WT was calculated, these results are shown in table 3.

Table 3. example results of p-Xylene

Conclusion

The SCION 8X00-GC analyser is perfectly capable of analysing trace impurities in monocyclic aromatic hydrocarbons with excellent repeatability and in compliance with ASTM D7504.

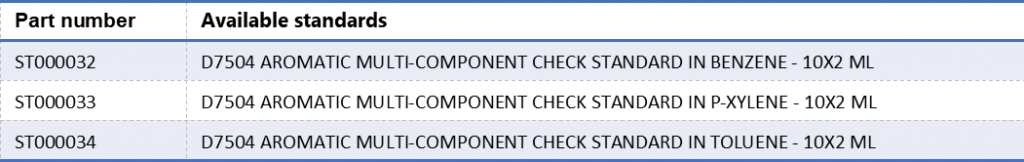

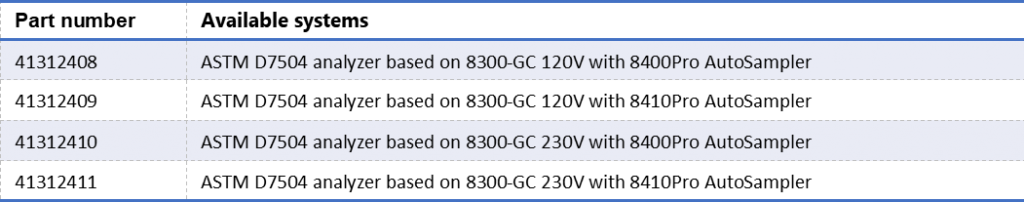

The equipment of the 8X00-GC analyser is pre determined. Ordering information can be found in the table below, for customisation please contact your local sales representative.

Although the 4X6-GC series is not shown in this application note, it is possible to perform this analysis on the SCION Instruments 4X6 GC series.

Order Information

Download Application Note

Download complete Application Note here: ASTM D7504 Standard Test Method for Trace Impurities in Monocyclic Aromatic Hydrocarbons by Gas Chromatography and Effective Carbon Number.

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, why not join us on social media and sign up to our Linkedin newsletters today?