Analysis of Mineral Oil Hydrocarbons utilising Temperature Programmed Large Vol Injections

Introduction

Mineral oil hydrocarbons are typically found in water, foods and soils. These hydrocarbons can be extracted using a variety of solvents, with the most popular being hexane and petroleum ether. As concentrations can be very low, sample enrichment is often required. However, SCION instruments developed a method that simply uses a Large Volume Injection (LVI) technique to simplify sample pre-treatment whilst dramatically increasing throughput.

The Hydrocarbon Index (HOI) is the total amount of compounds which can be extracted from water samples using a non-polar solvent. The solvent must have a boiling point between 39℃ and 69℃, thus replacing the use of halogenated solvents. Halogenated solvents and high concentrations of polar substances can interfere with the determination of the HOI. In addition, the compounds must not absorb on Florisil and must elute between n- decane and n-tetracontane. The method is suitable for HOI determinations in concentrations above 0.1mg/L in water samples.

This application note describes the highly efficient analysis of mineral oil hydrocarbons in water using the SCION 8500 GC equipped with a Programmable Temperature Vaporiser (PTV). The system is very well suited to the DIN-EN-ISO 9377 method and it can be visualized in Figure 1.

Figure 1. SCION Instruments 8500 GC

Experimental

Five calibration standards were prepared in hexane at various concentrations; 0.2mg/mL, 0.4mg/mL, 0.6mg/mL, 0.8mg/mL and 1.0mg/mL. A blank sample was also prepared.

A reference sample containing mineral oil hydrocarbons was obtained from the National Institute for Public Health and the Environment (RIVM). The test sample contained alkanes for HOI analysis. All samples were prepared by dissolving the alkanes in hexane.

Table 1 details the analytical parameters used throughout this application.

Table 1. Instrumentation operating conditions

| Conditions | |

| PTV | 70µL, 45°C (0.45min), 200°C/min to 350°C (8 min) |

| PTV Split | Initial ON 75

0.45min OFF 100 3.00min ON 150 |

| Liner | SCION Mineral Oil Liner |

| Column | Mineral Oil 15m x 0.32mm x 0.15µm |

| Oven | 35°C (4 min), 60°C/min to 150°C, 50°C/min to 250°C, 30°C/min to 350°C (1.50 min) |

| FID | 350°C |

Results

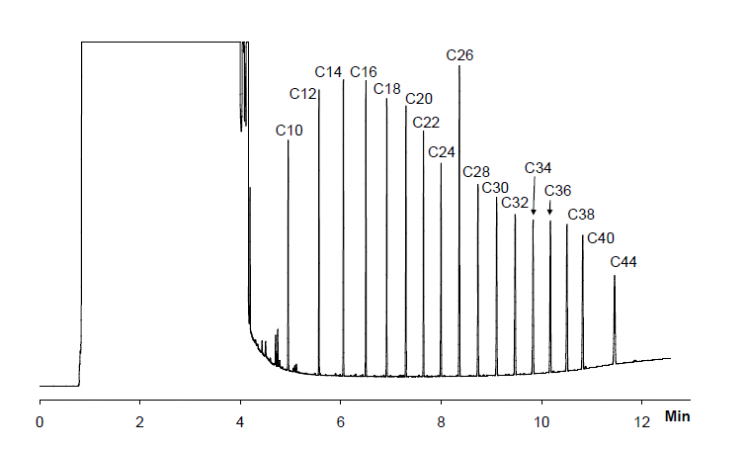

The sample was introduced in the PTV at a temperature that equals the boiling point of the solvent. Initially, the split was open allowing much of the solvent to evaporate from the vent. After 0.17 minutes, the split vent closed and the temperature increased. This allowed the evaporation and injection of the sample onto the column. Figure 2 shows a chromatogram from a calibration standard.

Figure 2. Chromatogram of a calibration standard

System suitability was checked via the C10 / C20 and C40 / C20 peak areas, with twenty injections of a low level calibration standard. The acceptable limits are defined as a peak are ratio between 0.8 and 1.2. Figure 3 shows the repeatability of both specifications.

Figure 3. Repeatability data on C10/C20 and C40/C20 (n=20)

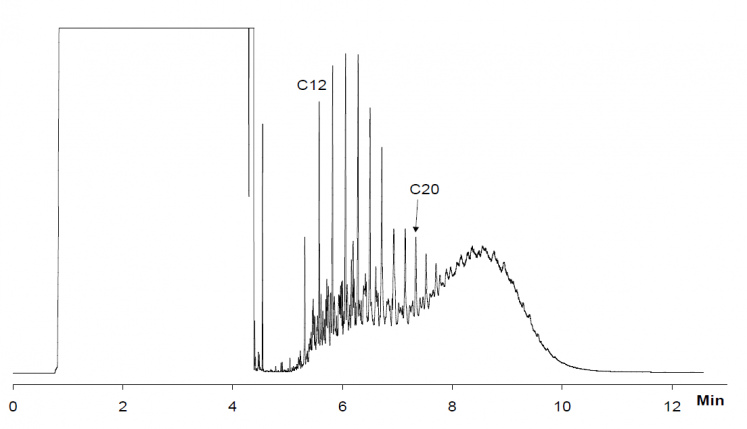

The high ratios obtained from the repeatability testing show a high recovery of the sample components and minimal discrimination. The high recovery was obtained from the specialised mineral oil liner which was optimised for longer retention of the sample components; this allows more of the solvent to be vented off and not introduced to the analytical column. With system suitability passing specification, the RIVM reference sample was analysed, as shown in Figure 4.

Figure 4. Chromatogram of RIVM reference standard

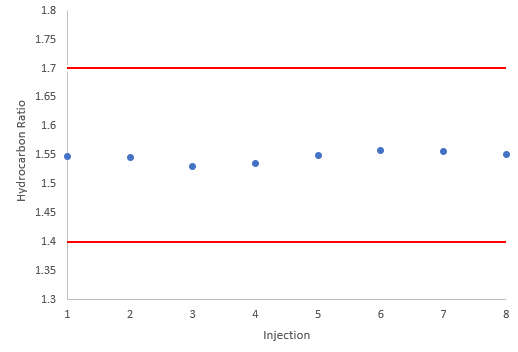

The reference sample was also subjected to repeatability testing (n=8), as shown in Table 2. Figure 5 details the repeatability of the hydrocarbon ratios.

Table 2. Repeatability of RIVM sample with hydrocarbon ratio (n=8)

| Run | Area

C10/C20 |

Area

C20/C40 |

HC Ratio |

| 1 | 1201944 | 1860482 | 1.55 |

| 2 | 1208160 | 1867571 | 1.55 |

| 3 | 1205740 | 1846199 | 1.53 |

| 4 | 1212651 | 1826599 | 1.51 |

| 5 | 1194517 | 1850616 | 1.55 |

| 6 | 1190457 | 1854374 | 1.56 |

| 7 | 1189986 | 1851458 | 1.56 |

| 8 | 1193781 | 1852083 | 1.55 |

| Average | 1199654 | 1851173 | 1.55 |

| St. Dev | 8640 | 11926 | 0.017 |

| RSD (%) | 0.72 | 0.64 | 1.11 |

Figure 5. Hydrocarbon ratios of RIVM sample (n=8)

The repeatability data clearly shows that the system is well suited to method DIN-EN-ISO 9377. The RSD% on peak area was 0.7% with a hydrocarbon ratio of 1.1%, clearly within the method specifications.

Conclusion

The system setup for this application was carefully optimised for measuring mineral oil hydrocarbons. The SCION mineral oil liner, mineral oil column and 8500 GC equipped with a PTV injector and high temperature FID all play a crucial role within this application. The optimised configuration ensures excellent results for the analysis of mineral oils. Hydrocarbon ratio analysis was 1.1% RSD, significantly within the specifications of DIN-EN-ISO-9377 which states that the value must be less than 14.1%.

Download the complete Application Note: AN020v2 – Analysis of Mineral Oils Utilising Temperature Programmed Large Volume Injection