Analysing Jet Fuel for Biofuel Contaminants – Safety First

SCION Instruments designs, develops, supplies and supports gas chromatography and mass spectrometry systems, specialising in custom GC solutions.

Calculating and reporting properties of petrochemical products is the most crucial part of any biofuel analysis. Samples range from gasoline up to crude oil with finished products being analysed to ensure that specific quality and environmental standards are met. ASTM (American Society for Testing and Materials) and DIN (Deutsches Institut für Normung) regulations stipulate that producers of biofuels and bioalcohol use gas chromatography to detect impurities in finalised products, including ethanol content in finished bioalcohol. Fatty Acid Methyl Esters (FAME), glycerine and glycerol are the main components targets during analysis.

Biodiesel is made from vegetable and animal fats into FAMEs. FAMEs are a surface-active material in which they are easily adsorbed onto pipelines and cargo vessels. Remaining FAMEs are then washed off onto the next product that fills the vessel. It is this cross contamination by common infrastructure that makes FAME analysis is critical, to ensure no contamination at the low ppm range. Due to the high freezing point and poor oxidative stability of biodiesel, it is not suitable for aviation use. Jet engines may stall because of filter blocking, fuel freezing or biological growth inside the aircraft fuel systems.

The chemical structure of FAMEs consist of non-polar hydrocarbon chains coupled to a polar methyl ester group. A GC/MS selective ion monitoring (SIM) /scan detection method has been developed (IP-585) by the Energy Institute and must be followed to determine that the cross-contamination level of biodiesel FAMEs in commercial A-1 jet fuel is less than 50ppm.

Due to the complex mixture of hydrocarbons in jet fuel, separation of polar FAME compounds can be difficult. The key challenge is the separation of C16:0 from the bulk jet fuel components. Completing a SIM analysis on a polar phase capillary column, coupled with a mass spectrometer (MS) eliminates any separation issues.

A mixture of the key 6 FAMEs with the addition of an internal standard was analysed on a SCION 436 GC with SCION single quad (SQ) MS, using the IP-585 SIM method. A SCION WAXMS column (50m x 0.20mm x 0.40mm) was used for the separation of FAMEs. The analytes of interest can be found in the table below.

| FAME | Quantifier/Qualifier Ions |

| C16:0 | 227.30, 239.30, 270.40, 271.40 |

| C17 | 241.30, 253.40, 284.40 |

| C18 | 255.30, 267.40, 298.40 |

| C18:1 | 264.40, 265.40, 296.40 |

| C18:2 | 262.40, 263.40, 264.30, 294.40, 295.40 |

| C18:3 | 236.30, 262.30, 292.30, 293.40 |

| I.S C17-d33 | 317.60 |

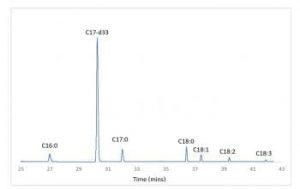

The high sensitivity of the SCION GC-MS system allows easy identification and quantification of clearly separated FAMEs in jet fuel. The chromatogram below details the separated FAME and internal standard at 2ppm, significantly lower than the upper 50ppm limit.

The SCION MS is designed for today’s fast paced analytical laboratory. Innovative design features such as a Lens Free ion path and an Extended Dynamic Range (EDR) detector enables the SCION SQ to deliver accurate quantification and identification on a routine basis even with the most complex matrices. The lens free ion path is a major advantage as less maintenance is required on the instrument. The user-friendly Mass Spectrometer Work Station software is easy to use and allows control of both the GC and MS system. Coupled with the SCION 8400 autosampler, the SCION GC-MS (SQ) allows a quick, automated solution for the most challenging petrochemical needs.