A Comparative Analysis of Fuel Oxygenates in Soil by Dynamic and Static Headspace Utilizing the HT3 Automatic Headspace Analyzer

INTRODUCTION

This application note presents method development using classical headspace sample preparative techniques for the analysis of fuel oxygenates in a soil matrix. Fuel oxygenate compounds were analyzed using the SCION Instruments HT3 Automated Headspace Analyzer in conjunction with a Gas Chromatograph/Mass Spectrometer (GC/MS) system.

Normal method validation including calibration, detection limit reporting, and reproducibility data was employed on the static and dynamic functions of the sampling system.

Figure 1. SCION HT3 Headspace Sampler together with the SCION Instruments 8300 GC platform in combination with to 8700 SQ-MS.

Fuel oxygenates have been added to gasoline for years. These additives aid in more efficient and cleaner fuel combustion thus reducing pollution. Unfortunately, since gasoline is stored in large storage tanks that are either above or below ground, fuel oxygenates can leach into the surrounding water or soil causing contamination and possible health risks to the surrounding environment.

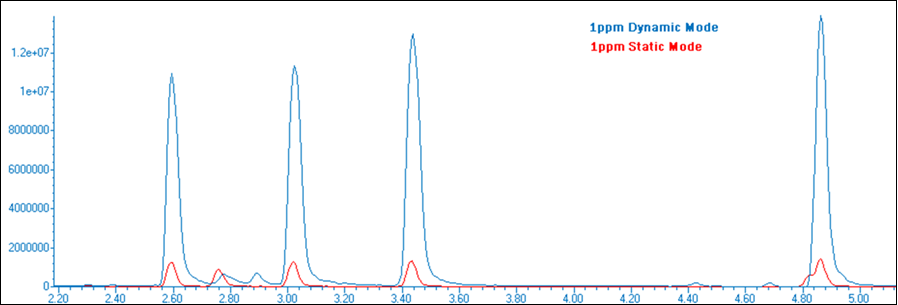

In this study, fuel oxygenates were evaluated by headspace analysis in both the static and dynamic modes at both a low part per billion (ppb) range and a high part per million (ppm) range on soil samples. The results were then compared to show the benefits of both modes of analysis. In particular, for analysis requiring lower levels of detection, the dynamic option is an excellent choice. Below is a brief description of the varying techniques.

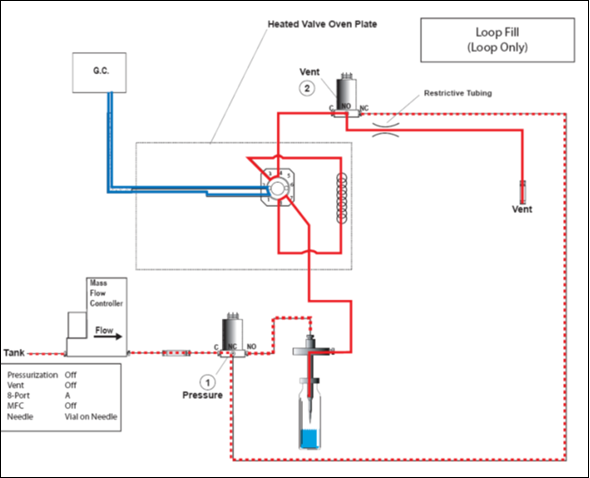

Static Headspace Extraction (Figure 2)

- A sample is placed in vial and sealed using a Teflon faced septa and metal containment cap.

- The sample is loaded into a heating chamber with temperature control for a set amount of time. This allows for equilibration between the matrix and headspace to occur depending on the partition coefficients of the analytes under investigation.

- At the conclusion of the heating step, the sample can be mixed using an agitation step and re-equilibrated.

- Sample is pressurized to a predetermined set point using an inert gas source.

- The sample is then vented to atmosphere though a fixed sample volume loop using either time or pressure feedback as the control.

- The sample contained in the loop is then injected for a set amount of time to a GC/MS for column separation and detection.

Figure 2. Static Headspace Extraction.

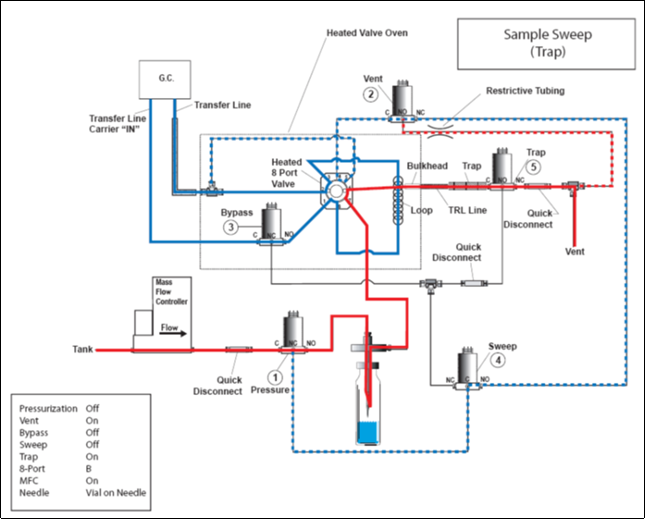

Dynamic Headspace Extraction (Figure 3)

- Steps 1 through 3 are the same as the static set-up

- The sample headspace is swept for a set time through a sorbent concentrating trap using the inert gas source. This function allows more sample from the matrix to enter the headspace as equilibrium between the two phases cannot occur.

- At the conclusion of the sweep step the sorbent trap is heated and back-flushed to the GC/MS system. This allows all of the analytes originally contained in the sample to be calculated in a single run.

Figure 3. Dynamic Headspace Extraction.

EXPERIMENTAL-INSTRUMENT CONDITIONS

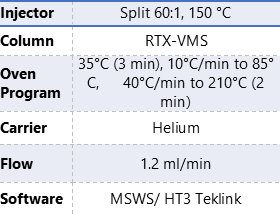

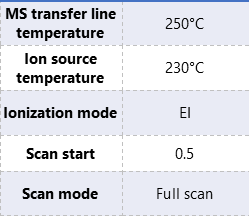

The SCION Instruments HT3 Automated Headspace Analyzer, an 8300 GC and a 8700 SQ-MS were used for this analysis. The HT3 has method development software called Method Optimization Mode (M.O.M.). This software was utilized in order to obtain the platen temperature for the dynamic and static experimental conditions and to find the optimum sweep time for the dynamic experiment. Table 1 displays the GC, MS, and the static and dynamic headspace experimental conditions.

Table 1. Instrumentation operating conditions.

CALIBRATION

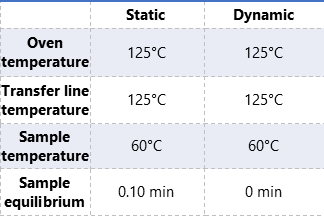

A 50ppm (dynamic) and a 200ppm (static) working calibration standard were prepared in methanol. Due to solubility issues, the tert-butyl alcohol (TBA) in the calibration standard was at a higher concentration than the other compounds, thus the concentration of the TBA was 250ppm for the dynamic calibration standard and 1000ppm for the static calibration standard. 5g of baked sand and 5mL of saturated sodium chloride solution were added to each 22mL headspace vial. The vials were then spiked with the calibration standard at different concentrations in order to run both the dynamic and static curves. Table 2 and 3 shows the curve preparation of the standards.

Table 2. Dynamic Mode Curve Preparation

Table 3. Static Mode Curve Preparation

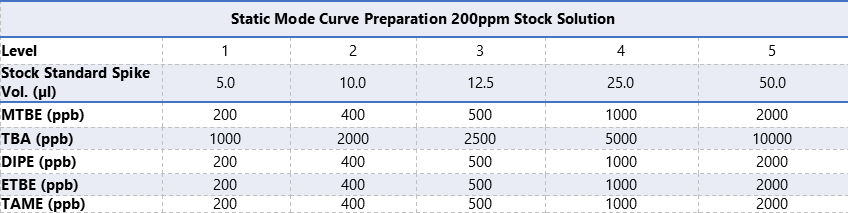

Method Detection Limit (MDL) Determination and Reproducibility Study

A statistical determination of the MDL’s was established for each analyte. Seven replicate standards of the low calibration point were analyzed in order to determine the MDL’s for each compound in both the static and the dynamic modes. The detection limits for the compounds in both modes are listed in Table 4.

In order to demonstrate the robustness of the experimental conditions, a reproducibility study was performed. Several replicate standards of a 100ppb concentration were run in the dynamic mode and a second set of 1000ppb standards were run in the static mode. The reproducibility data for both modes was then analyzed and these results are also presented in Table 4.

Table 4. Data Summary

Figure 4: 1ppm Fuel Oxygenate Standard in Dynamic and in Static Mode

CONCLUSIONS

The HT3 Automated Headspace Analyzer is an excellent system for the analysis of fuel oxygenates in soil. The dynamic capabilities of the HT3 allow analyte detection down to a 5ppb level while the static mode can be used for samples with higher, 200ppb, level components. Both the static and dynamic modes of the HT3 provided linear calibration curves and excellent reproducibility while providing a wide sample detection range. The versatility of the HT3 allows switching between both the static and dynamic modes of the instrument within a schedule enabling better use of instrument time, flexibility to test for both high and low level components, and less hands-on time requirements from laboratory personnel. In addition, the M.O.M. feature allows all parameters to be automatically adjusted to help users find the best conditions for their required analysis and a complete history log of how it was achieved.

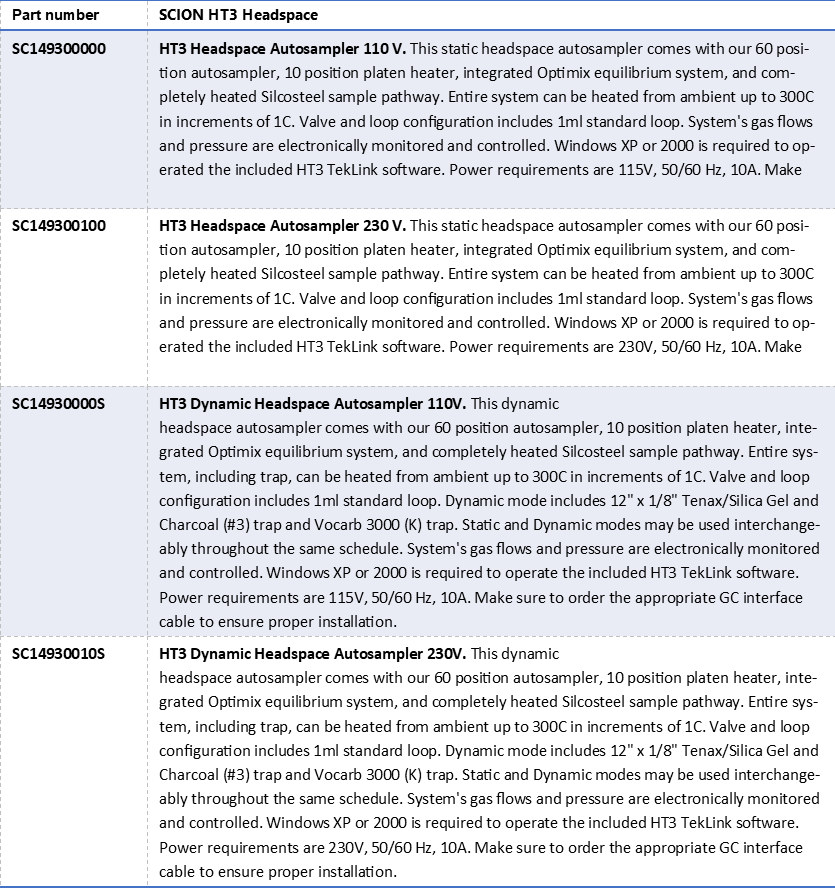

ORDER INFORMATION

Download the Application Note

Download our full Application Note: A Comparative Analysis of Fuel Oxygenates in Soil by Dynamic and Static Headspace Utilizing the HT3 Automatic Headspace Analyzer

Keep in Touch

If you wish to keep up to date with SCION Instruments latest research and articles, follow us on social media and sign up to our newsletter below.