Determination of Free Glycerol Content in Fatty Acid Methyl Esters (FAME) and Biodiesel According to EN-14106

Introduction

Biodiesel is produced from oils such as vegetable oils, used cooking oils and animal fats – the fuel is produced by a process called transesterification. The oils and fats are converted into biodiesel and glycerol by reaction with an alcohol (usually methanol) in the presence of strong base such as potassium hydroxide or sodium hydroxide. The strong base behaves as a catalyst for the reaction – alkoxides are also increasingly used within the industry. Glycerol is formed as a by-product and separated from the biodiesel during the production process. However, traces of glycerol can be found in the final biodiesel product. In higher concentrations, glycerol has a negative effect on fuel behaviour and performance.

For biodiesel to be used as a motor fuel or blended with petroleum diesel, it must conform to standard specifications (ASTM D6751 or EN 14214). There are GC methods to determine whether biodiesel conforms to the standard specifications. One of these methods, EN 14106, is used to determine the glycerol content. EN 14106 specifies a gas chromatographic method for the determination of free glycerol content in Fatty Acid Methyl Esters (FAME) in the range of 0.005 % to 0.070 %.

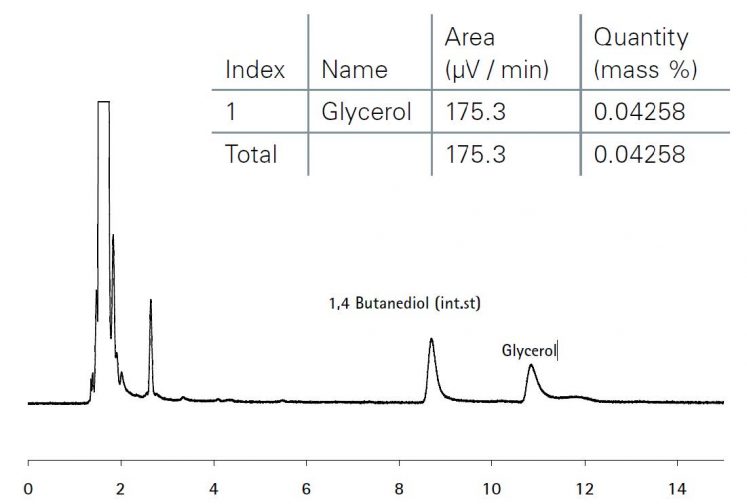

Fig. 1 Biodiesel Chromatogram

Experimental

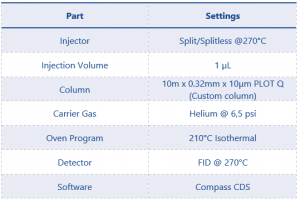

The SCION Biodiesel analyser for EN 14106 is based on our 8300-GC platform, a cold-on-column injector, a SCION-Glycerides Inert Steel analytical column with a 2 m retention gap and a High-Temp FID Detector. Analytical conditions for the EN 14106 analysis can be found in Table 1.

Table 1. GC Parameters

Sample Preparation

Ethyl alcohol, water, hexane and a known amount of internal standard were added to a known quantity of sample.

Please note that when these solvents are added together, two phases are formed. The free glycerol ‘transferred’ into the lower of the two phases.

Approximately 3.5 g of sample was weighed into a 10 mL test tube. 1 mL of ethyl alcohol was added and gently shaken to ensure uniform mixing. Exactly 1 mL of internal standard solution and 4 mL of hexane were added. The tube was tightly plugged and shaken vigorously for ~ 5 minutes. After an ~15 minutes centrifuge, the lower phase was used for gas chromatographic analysis.

Calibration and Calculation

A calibration mix containing known quantities of 1,4 Butanediol and Glycerol was used to determine the response factor of Glycerol.

Response Factor (Fr) = (A1/M1)/(A2/M2)

Where:

A1 is the peak area of internal standard

A2 is the peak area of Glycerol

M1 is the mass of 1,4

Butanediol in response factor solution, expressed in mg

M2 is the mass of glycerol in response factor solution, expressed in mg

The results were calculated using the following equation:

Free Glycerol, % (m/m) = (((A2/A1) * Fr * m1)/m)*100

A1, A2, Fr see formula 1

m1 mass of int std in sample (mg)

m mass of sample (mg)

Results

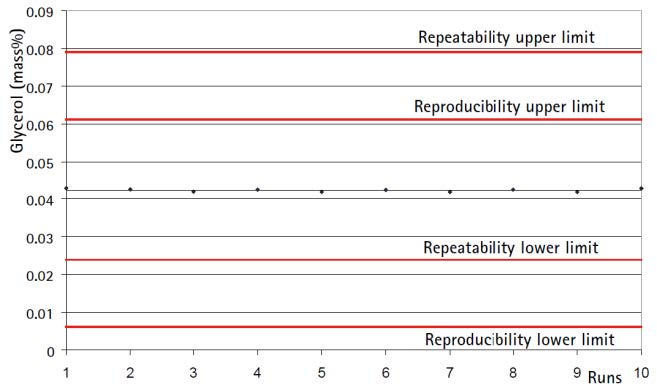

The sample of biodiesel used in this application was analyzed multiple times. A chromatogram of this analysis is shown in figure 1. Table 2 shows the repeatability figures, average and standard deviation. Figure 2 shows the individual numbers compared to repeatability and reproducibility limits described in the EN 14106 method.

| File | Glycerol (% m/m) |

| 1 | 0,04306 |

| 2 | 0,04275 |

| 3 | 0,04213 |

| 4 | 0,04267 |

| 5 | 0,04205 |

| 6 | 0,04258 |

| 7 | 0,04205 |

| 8 | 0,04268 |

| 9 | 0,04205 |

| 10 | 0,04299 |

| Average | 0,04250 |

| STDEV | 0,0003984 |

| STDEV (%) | 0,94 |

Table 2. Repeatability results for Glycerol in Biodiesel

Fig. 2 Repeatability based on 10 runs. Red lines indicate the maximum and minimum variation limits of the method.

Conclusion

This application note demonstrates the suitability of SCION Instruments for EN 14106, for the analysis of free glycerol in biodiesel. The repeatability data demonstrates good system integrity. Therefore, the system is well suited to the analysis of free in biodiesel in accordance with the standard method EN 14106.

Download the Application Note

You can download the complete application note as a pdf: Download Application Note