Propane Aromatization - Case Study

Propane Aromatization – Catalytic Applications with Gas Chromatography

Propane aromatization plays a pivotal role in the petrochemical industry by converting light alkanes such as propane into aromatic hydrocarbons like benzene, toluene, and xylenes (BTX). These aromatics are essential precursors for polymers, plastics, and high-octane fuels. The process typically involves heterogeneous catalysis under specific temperature and pressure conditions to achieve high yields of aromatics while minimizing unwanted by-products. Evaluating catalyst performance is critical for enhancing process efficiency and economic viability. Gas Chromatography has emerged as a versatile technique for real-time analysis of reaction products, enabling precise measurement of catalyst effectiveness and product distribution.

Gas Chromatography for Catalyst Evaluation

In propane aromatization studies, Gas Chromatography is employed to analyze the effluent from the reactor where propane is converted into aromatic hydrocarbons. The GC system is equipped with appropriate detectors to monitor the presence and concentration of benzene, toluene, xylenes, and other relevant compounds. Samples are typically collected periodically during the reaction to assess changes in product distribution and catalyst performance over time. Advanced GC techniques such as temperature-programmed desorption (TPD-GC) or GC coupled with mass spectrometry (GC-MS) may be utilized for detailed characterization of reaction intermediates and by-products.

Applications and Benefits

Quantitative Analysis:

- Provides accurate measurement of aromatic hydrocarbon yields and selectivity, essential for comparing catalyst performance.

Reaction Kinetics:

- Enables real-time monitoring of reaction kinetics, identifying optimal reaction conditions for maximizing BTX production.

Catalyst Stability:

- Evaluates catalyst stability and resistance to deactivation mechanisms such as coke formation or metal leaching.

Process Optimization:

- Facilitates adjustments in catalyst design and operating parameters to enhance overall process efficiency and economic viability.

Customer Case Example

In the following example, SCION Instruments worked with our customer to provide a Gas Chromatography based analytical tool for evaluating catalysts in propane aromatization, offering insights into reaction kinetics, product distribution, and catalyst stability. By leveraging the SCION GC’s capabilities, it is possible to optimize catalyst design and reaction conditions to achieve higher yields of aromatic hydrocarbons while minimizing energy consumption and environmental impact.

Method

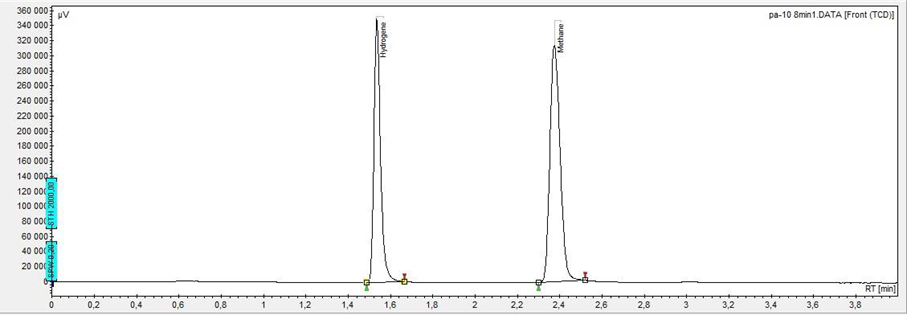

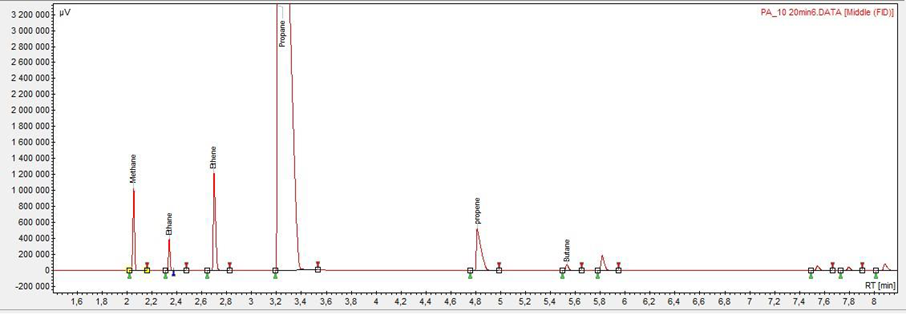

The reactor effluent is collected and sampled at 1, 4, 8, 12, 16, 20, 30, 40, 50 and 60 minutes, using a multi-position Valco valve and then is analyzed into GC-FID. During sampling in the 10-port valve loops, the TCD continuously analyzes the quantities of hydrogen and methane.

The results obtained from the SCION GC analysis provide the total areas of each constituent. These total areas serve as quantitative measures of the amounts of each compound produced during the reaction.

By comparing the total areas of the starting material (propane) with those of the desired product (benzene, toluene) and any undesired by-products, they can calculate subsequently the conversion, selectivity, and turnover frequency of the reaction.

These calculations provide valuable insights into the efficiency and performance of the catalyst system, allowing for optimization and improvement of the reaction conditions to enhance product yield and selectivity.

System Configuration

Propane Aromatization:

SCION 8500-GC 2 channels

1st channel : GSV, two columns Shincarbon ST & Hayesep Q (backflush) and TCD à H2 & methane determination

2nd channel : 10 loops selecting valve, GSV, S/SL injector, column SCION-DHA and FID à hydrocarbons determination

Software : CompassCDS

Download Case Study – Propane Aromatization

Whether you are a researcher, a process engineer, or an industry professional, you will gain valuable knowledge to advance your understanding and application of catalysts using gas chromatography. Take a look at our additional case studies:

Toluene hydrogenation – Case Study

CO2 methanation – Case Study

Ammonia synthesis – Case Study

Toluene Methanolation – Case Study