Toluene Methanolation - Case Study

Toluene Methanolation – Catalytic Applications with Gas Chromatography

Toluene methanolation is a catalytic process aimed at transforming toluene (C₆H₅CH₃) into methylbenzene (C₆H₄CH₃OH) by adding methanol (CH₃OH). This reaction holds industrial significance due to methylbenzene’s versatility as a chemical intermediate in the production of solvents, adhesives, and pharmaceuticals. Continuous monitoring and optimization of toluene methanolation are crucial for maximizing product yield and minimizing energy consumption. Gas Chromatography is an effective analytical technique for online analysis, enabling real-time measurement of reaction dynamics and product formation.

Online Analysis in Toluene Methanolation

Gas Chromatography can be used for online analysis to continuously monitor concentrations of toluene, methylbenzene, methanol, and other gas-phase species present in the reactor effluent. Automated sampling systems collect periodic samples from the reaction mixture, which are then injected into the GC system for separation and detection. Advanced techniques such as GC-MS may be employed for enhanced specificity and identification of trace components, aiding in comprehensive analysis of reaction intermediates and by-products.

Applications and Benefits

Real-time Monitoring:

- Enables continuous tracking of reaction kinetics and product distributions, facilitating rapid adjustment of reaction parameters for optimal performance.

Quantitative Analysis:

- Provides accurate quantification of methylbenzene yield, toluene conversion efficiency, and methanol utilization, crucial for optimizing catalyst design and process conditions.

Catalyst Evaluation:

- Evaluates catalyst activity, selectivity towards desired products, and resistance to deactivation mechanisms, supporting the development of efficient catalytic systems.

Process Optimization:

- Facilitates fine-tuning of operational variables such as temperature, pressure, and catalyst composition to maximize methylbenzene production while minimizing environmental impact and energy consumption.

Customer Case Example

In the following example, SCION Instruments worked with our customer to provide a Gas Chromatography based analytical tool for online analysis during the toluene methanolation processes, offering real-time insights into reaction dynamics, product distribution, and catalyst performance.

By leveraging the SCION GC’s capabilities, it is possible to optimize reaction conditions, enhance catalyst efficiency, and advance sustainable practices in chemical synthesis.

Method

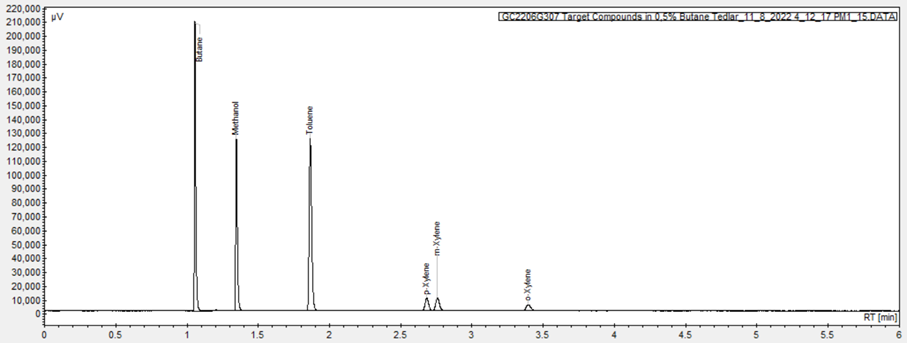

The SCION GC is used to perform online analysis of the toluene methanolation. The quantification of toluene, methanol and xylene isomers will be done on a FID.

The results obtained from the SCION GC analysis provide the total areas of each constituent. These total areas serve as quantitative measures of the amounts of each compound produced during the reaction.

By comparing the total areas of the starting material (toluene and methanol) with those of the desired product (xylene isomers) and any undesired by-products, they can calculate subsequently the conversion, selectivity, and turnover frequency of the reaction.

These calculations provide valuable insights into the efficiency and performance of the catalyst system, allowing for optimization and improvement of the reaction conditions to enhance product yield and selectivity.

Sub sub heading: System Configuration

Toluene Methanolation:

SCION 8300-GC

GSV, S/SL injector, column S-WAX and FID à methanol, toluene & xylenes determination

Software : CompassCDS

Download case study – Toluene Methanolation

Whether you are a researcher, a process engineer, or an industry professional, you will gain valuable knowledge to advance your understanding and application of catalysts using gas chromatography. Take a look at our additional case studies:

Toluene hydrogenation – Case Study

CO2 methanation – Case Study

Propane Aromatization – Case Study

Ammonia synthesis – Case Study