Determination of Limonene in Recycled HDPE Pellets

Introduction

Over four and a half million tonnes of plastic is produced annually in the UK alone, with over 85% of this going to landfill (1). Over 45% of plastic bottles are sent to recycling with the number expected to significantly increase in the coming years. Recycled plastics have a variety of uses from new bottles/ food trays to underground draining products and soft furnishing materials (1).

During the recycling process, clear and mixed colour plastics are separated before they are granulated and re-separated. The granulated plastics are then thoroughly cleaned and dried before being tested in quality control and sent to be manufactured. The plastics are turned into high density polyethylene (HDPE) pellets. It is vital that the pellets produced from the recycling are deodorised from contaminants and flavour compounds especially when they are manufactured into food packaging.

Limonene is a cyclic monoterpene and is the major component of the oil in citrus fruits. Limonene contaminates recycling materials; during the recycling process, high levels of limonene in the pellets must be removed during deodorisation (2). During quality control testing, the pellets must have a limonene concentration of less than 20ppm. This application note demonstrates the extraction of limonene from the HDPE pellet with excellent limit of detection using the highly sensitive SCION 8300 GC with single quad (SQ) mass spectrometer (MS).

Experiment

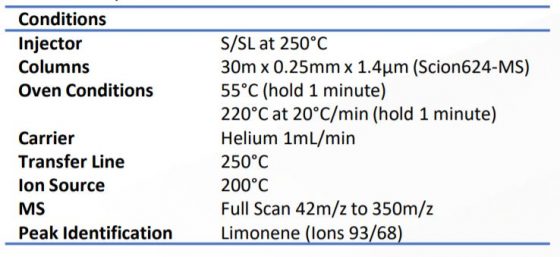

Table 1 details the analytical parameters used throughout this application.

Table 1. Analytical conditions of the GC-MS

Limonene calibration standards were prepared in Carbon Disulphide (CS2) at a range of 0ppm, 5ppm, 10ppm, 20ppm and 40ppm.

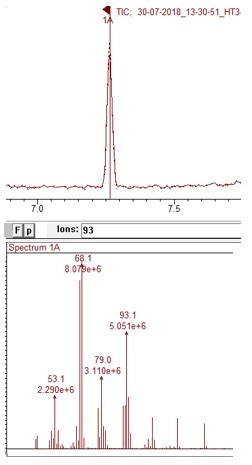

0.1g HDPE pellets were extracted using 1mL of CS2 and incubated at room temperature for sixty minutes. The extracts were then injected into the GC using a 8400 autosampler. The HDPE pellets were analysed in triplicate. A full scan method was used to identify m/z 93, the quantifier ion of limonene with m/z 68 as a qualifier ion. The total ion chromatogram (TIC) was subjected to a NIST library search for confirmation.

Results

The limonene was identified with a retention time of 7.265 minutes using the full scan method and injection of an analytical standard. Figure 1 shows the TIC of limonene and the associated spectra obtained via the full scan method.

Figure 1. Limonene TIC and spectra

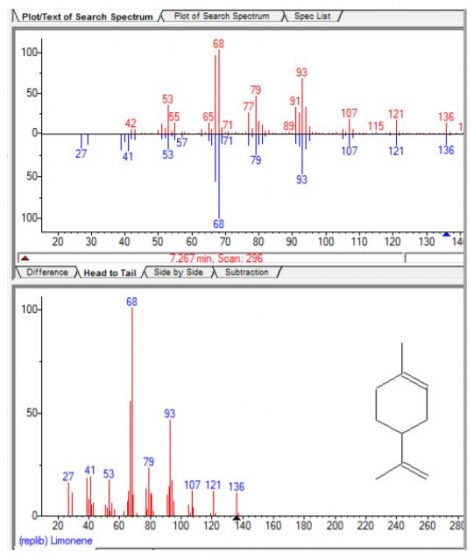

A NIST library search of the limonene peak gave a spectral match of 91%. Figure 2 shows the NIST library search, generated through the SCION Mass Spectrometry Work Station (MSWS) software.

Figure 2. NIST library search; 91% match

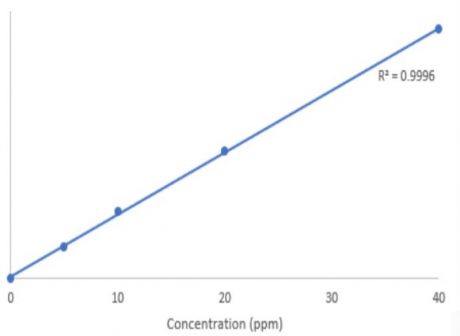

After accurate identification of limonene, via the NIST library, the calibration standards were analysed in triplicate. A blank sample was also analysed for quality control purposes. Figure 3 shows the calibration curve generated from the triplicate injections, using the average of the replicates.

Figure 3. Calibration curve of limonene

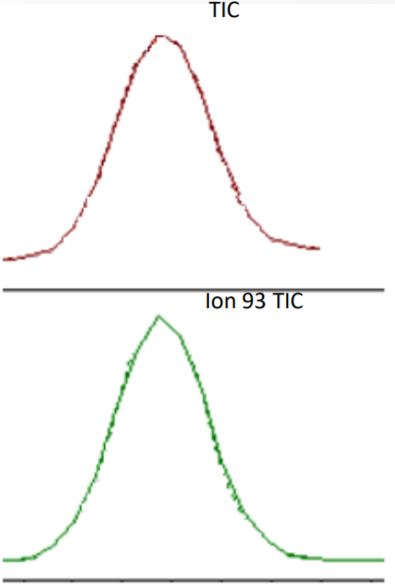

The calibration showed excellent linearity with an R value of 0.9996. The HDPE pellets were then also analysed in triplicate (three separate samples prepared). Retention time and extraction ion 93 were used for confirmation of the limonene. Figure 4 details the TIC and TIC for ion 93.

Figure 4. TIC and Ion 93 TIC of HDPE pellet

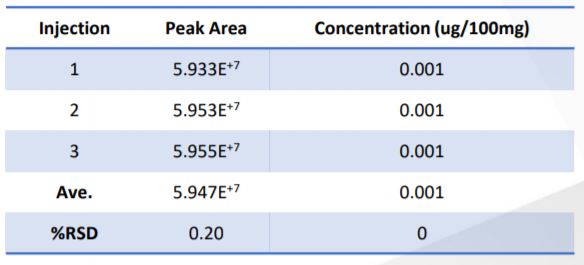

The calibration curves were used to calculate the concentration of limonene in the samples. Table 2 details the peak area and calculated concentration of each injection as well as the average peak area, average concentration and RSD% of the analysis.

As shown in table 2, the %RSD for the peak area was exceptional, at only 0.20%, with the %RSD of calculated concentration being zero. This shows the robustness of the SCION 8300 GC with SQ MS. The concentration of limonene in the HDPE pellets was 0.01µg/g (0.01ppm), well below the 20ppm limit allowed to be present in recycled plastics. This extremely low presence of limonene in the pellets demonstrate that the recycled plastics were successfully deodorised during the milling process.

Conclusion

The high sensitivity and robustness of the SCION GC-MS coupled with a simple sample extraction made analysis of the HDPE pellets quick and easy, generating confident, reproducible results. The analysed HDPE pellets contained 0.01ppm of limonene. The limonene concentration was significantly lower than the 20ppm limit clearly showing that the pellets have been deodorised, thus passing quality control.

Download Application Note

Download the complete Application Note: Determination of Limonene in Recycled HDPE Pellets

SCION’s Gas Chromatography Analyser

Our Gas Chromatography Analyser was used to conduct this research. Providing excellent solutions for Environmental, Oil and Gas and Chemical industries, find out more about SCION GC Analysers. Alternatively if you would like to discuss any specific requirements you may have simply contact us. We look forward to being of assistance.

References

[1] Viridor.co.uk. (2018). Plastic Recycling. [online] Available at: https://viridor.co.uk/our-operations/recycling-andresources/plastic-recycling [Accessed 28 Aug. 2018].

[2] Welle, F. (2005). Develop A Food Grade HDPE Recycling Process. Oxon: The Waste & Resources Action Programme, p.4.